As the range of substrates, inks, and printing technologies has expanded, so has the challenge of maintaining color quality for brands and printers. A workflow based on digital standards is the easiest way to achieve accuracy and consistency across shifts and sites, regardless of production requirements. Adding a quality control solution like ColorCert® to your workflow can boost your bottom line even more.

As the range of substrates, inks, and printing technologies has expanded, so has the challenge of maintaining color quality for brands and printers. A workflow based on digital standards is the easiest way to achieve accuracy and consistency across shifts and sites, regardless of production requirements. Adding a quality control solution like ColorCert® to your workflow can boost your bottom line even more.

What is ColorCert?

ColorCert is a modular, job-based solution that streamlines color communication across the print workflow and offers root cause analysis if color issues arise. Utilizing a combination of ColorCert modules, every stakeholder in the workflow – including brands, prepress, inkroom, and pressroom, in one site or many – can be linked. This allows proper communication of color and print expectations, tolerances, and press setup information.

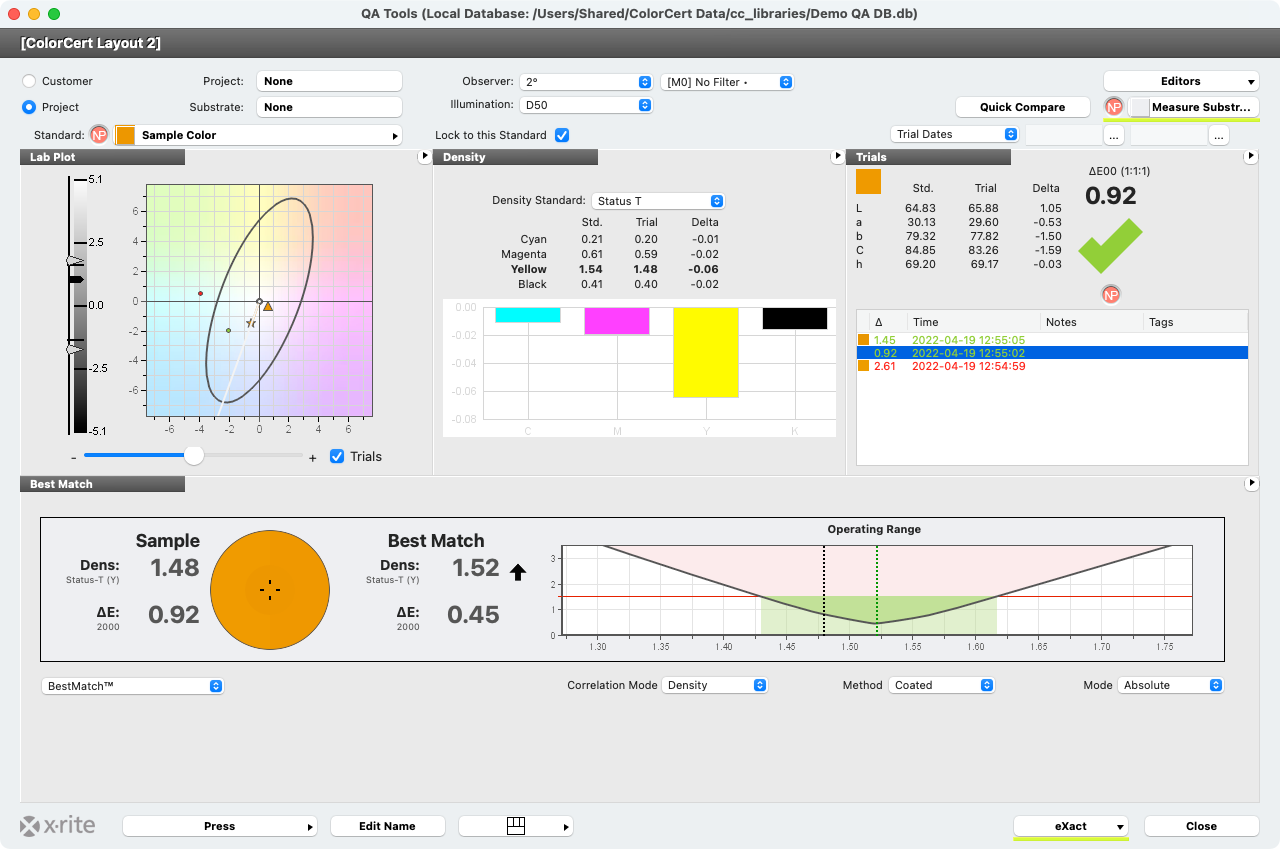

In the press room, ColorCert simplifies feedback to operators so they can spend less time reviewing data. The BestMatch feature offers actionable information to apply corrective actions and actually see the results during the run.

For ink suppliers, ColorCert integrates with InkFormulation software and offers a central repository to manage brand colors and share color data with printers and brands.

For pre-media and production managers, ColorCert offers an easy way to distribute color standards and analyze massive amounts of data. If a job score is low, it’s easy to analyze the causes and gain insight into ways to optimize production by streamlining and improving processes.

Brands can take advantage of the full ColorCert suite to monitor color throughout the workflow and track quality across jobs and suppliers without onsite press checks and focus on sustainability initiatives.

ColorCert Modules

ColorCert provides specific modules focused on each part of the workflow, helping flexo, gravure, and offset printers remove subjectivity, analyze data, and deliver increased productivity for the packaging industry.

ColorCert Desktop Tools ColorCert Desktop Tools

For print and packaging converters to create accurate color specifications and control processes at multiple points throughout the packaging workflow but do not need to compare job runs across site. |

|

For converters who measure color and want actionable guidance to improve color performance and ink suppliers who need database and basic charting tools to review color match performance over time. |

ColorCert Repository Server ColorCert Repository ServerFor brands, pre-media, and print and packaging converters to manage and deploy the most up-to-date digital assets, move work between locations, and compare job runs across site from a central, cloud-based source. |

ColorCert ScoreCard Server ColorCert ScoreCard Server

For brands and pre-media who work in complex global supply chains to get an overall view into supplier print quality without on-site press checks. |

How Asda Walmart Uses ColorCert

When combined with other X-Rite solutions, ColorCert paves the way for a complete, digital color workflow to increase accuracy and speed. According to Jason Gilmartin, Senior Print Manager at Asda, "ColorCert is an important pillar of the Asda Print Team's strategy for managing the quality of Brand Print. Ensuring that our print partners have the right solutions in place is key to them taking full responsibility for raising and maintaining the quality of their product."

Ultimate Packaging

Ultimate Packaging was invited to try PantoneLIVETM and ColorCert by Asda, a wholly owned subsidiary of Wal-Mart and a key customer for Ultimate Packaging, as part of Asda’s objective to maximize supply chain efficiencies. “We were happy to do so, but at the time we didn’t really think it would make a great deal of difference to our operations,” said Vincent Whatley, X-Rite Coordinator at Ultimate Packaging. “In actual fact, it has made a big difference for us and for Asda.” Ultimate Packaging implemented ColorCert on its newest F&K flexible packaging press where 20% of the work produced is for Asda.

A provider of flexible packaging solutions to a broad array of customers, the company has six flexo presses (8 and 10 colors) in a 100,000 square foot manufacturing plant. “ColorCert gave us visibility into problems we were not aware we had, including with our ICC profiles, ink formulation and proofs.”

To properly understand print performance, Ultimate utilizes 100%, 70% and 40% patches in their color bar. They are able to place these color bars within the artwork, not restricted to the outer edges of the sheet, to make better use of real estate on expensive substrate. Utilizing the eXact Scan, the press operator scans each roll of material to make sure the proper color and print performance expectations are being maintained. Once the job is completed, the data is automatically uploaded (without a secondary process) to the Asda ScoreCard Server so both Asda and Ultimate Packaging can view quality trending and have fact-based discussions about quality. This dynamic drives clarity of expectations and proactive quality improvement.

Asda can also see which instrument has been used and verify that instruments have been certified with NetProfiler, which gives them confidence in a reliable, closed-loop color measurement and management process.

In order to provide sufficient data for full analytics, Ultimate Packaging reports on all of the work the press produces, making the information available through ColorCert Scorecard, so that Asda can see how the press is performing overall.

- A more efficient ink kitchen.

Ultimate Packaging partners with Sun Chemical for onsite ink formulation and dispensing. X-Rite InkFormulation Software and X-Rite color measurement instruments have been key to ensuring that the correct inks are delivered and that inks are formulated accurately for each job. They also use PantoneLIVE digital color standards, integrating with InkFormulation Software and ColorCert Inkroom Tools for increased efficiency, more accurate ink formulation, and less waste on press. - Improved premedia.

Ultimate Packaging partners with a number of repro houses for prepress operations, and ColorCert has enabled them to reduce the amount of retouching required, improving the quality of the profiles being used. “With the data we gathered using ColorCert, we learned a great deal about repeatability, as well as hitting the scores and ICC targets through fingerprinting. It has also helped us work out how variables such as heat, viscosity and temperature were affecting our outcomes. It was a big learning curve, and as a result we have up-skilled our staff and significantly improved our performance and our communication with our repro house partners,” Whatley says. - More accurate production.

ColorCert Scorecard has helped Ultimate Packaging easily identify areas to improve performance. This ensures that profiles are correct, plates are correct, inks are accurate, and the company’s partners better understand what is needed. The result? An improvement of 200% in Ultimate’s ColorCert score! - Better customer relationships.

Since implementing ColorCert, Ultimate has a better awareness of what is coming into the building and what is leaving. “Our relationship with Asda was always good, but it has really improved since we implemented PantoneLIVE and ColorCert.” Whatley states. “Having the ColorCert Scorecard in place has given performance visibility to all authorized parties in the supply chain. This helps with communication, putting everyone at ease, knowing that product delivered will be consistent and of highest possible quality.

Learn More About Asda's Digital Print Program

- Download the full Ultimate Packaging case study to learn how the packaging company also integrates X-Rite handheld solutions for color measurement and InkFormulation Software for its ink kitchen, managed by Sun Chemical. It’s a successful workflow that has made Ultimate Packaging much more confident in their ability to print to the numbers.

- Download the Asda case study to learn how Asda was able to remove subjectivity from their brand color process and enabled their suppliers to intelligently manage color quality with real-time measurable data.

- Read the Asda Walmart Color Quality Program blog to learn how Asda is rolling out a digital color quality program to their Chinese packaging supply chain.

Learn More about ColorCert

If you’d like to learn more about the practical application of ColorCert in a digital packaging workflow, we encourage you to watch the Intro to ColorCert videos. If you still have questions, get in touch and a Color Expert can help.