Color Harmony for Automotive Part Suppliers

Color is becoming more important in car designs, adding complexities for both manufacturers and part suppliers. To set clear expectations, automotive manufacturers must specify both color and appearance and establish strict color tolerances for each colored component. To ensure color acceptability with the automotive manufacturer, part suppliers must control and produce color accurate parts, regardless of material type.

For part suppliers, achieving harmony between substrates like coatings, plastic, rubber, fabric and leather is a challenge. However, it’s important to manufacturers because mismatched color can slow time to market and impact a significant number of vehicles. How do part suppliers deliver color accurate parts and avoid costly rejections? To control and manage color consistency, part suppliers need reliable solutions to measure color and ensure harmony between parts before shipping to the manufacturer.

Customizable tools from X-Rite enable part suppliers to:

- Communicate and verify color specifications to set clear expectations.

- Evaluate special effect finishes found on exterior automotive painted parts 60% faster to reduce rejections.

- Identify color defects on parts early in the manufacturing process to avoid unnecessary repair costs.

- Increase initial match rate by up to 50% and cut color correction steps in half.

Quality Control for Automotive Part Suppliers:

A reliable and easy-to-use quality control program ensures color is within tolerance, reducing manufacturer rejections. Equipping your team with the right color measurement tools will ensure color harmony among all parts at final assembly.

- MA-5 QC Multi-Angle Handheld Spectrophotometer: Validate whether parts containing metallic or effect finishes are within manufacturer specification before shipment.

- EFX QC Software: Track color measurement data on automotive parts to gauge quality and look for areas of improvement to increase overall profitability.

- Ci64 Sphere Handheld Spectrophotometer: Measure smooth and textured surfaces like interior car seats and trim pieces with greater accuracy.

- Color iQC Software: Receive actionable data to identify why color errors occur and enable swift production adjustments so final parts meet manufacturer specifications.

Formulation for Automotive Part Suppliers:

Formulating color can be a lengthy and tedious process, especially with a manual process. X-Rite’s color formulation solutions reduce the number of iterations to get an initial color match on automotive parts and minimize correction steps to save time and money.

- Ci7800 Benchtop Spectrophotometer: Seamlessly communicate and coordinate color-critical values and specifications to set clear specifications and ensure color integrity of interior and exterior car parts.

- Color iMatch Software: Achieve optimal initial color matches, reduce wasteful formulation attempts, and eliminate mismatched car parts.

Inline Color Measurement for Part Suppliers:

Measuring and monitoring color on the production line is key to ensuring stable and accurate color, minimizing cost and waste that can result in thousands of dollars in financial loss. X-Rite solutions provides part suppliers the tools they need to avoid these costly line errors and rework.

- ERX50 Non-Contact Inline Spectrophotometer: Manage the color of materials on continuous production lines like plastic and leather, to ensure color shifts are detected early.

- ERX130 Non-Contact Spectrophotometer: Provide automated inline color measurement across a wide-range of materials including vinyl, textiles and paints.

- ESWIN Quality Control: When combined with an X-Rite inline color measurement instrument, ESWin Quality Control manages color quality on continuous process manufacturing lines, displays results, and runs automatic in-line closed-loop color control.

Featured Resources

In this free 10-minute webinar, you will learn why a multi-angle is the ideal spectrophotometer to measure special effect surfaces, like metallic and pearlescent.

Learn how the MA-5 QC multi-angle spectrophotometer, together with EFX QC software, improves color evaluation accuracy and validates whether parts are within specifications.

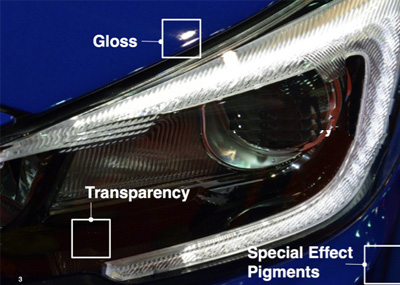

Objects have elements that are inherent to appearance, such as texture, gloss, transparency and special effects. To control color, you must understand them.