This is the first blog in our MeasureColor in Action blog series, which introduces key features to help you achieve smarter, more efficient print production.

MeasureColor: A User-Friendly Interface for Faster Print Decisions

In today’s print industry, finding skilled press operators is more challenging than ever. At the same time, production environments are becoming increasingly complex—often combining multiple printing techniques and a wide range of press makes and models. That’s why intuitive, easy-to-use tools are no longer a luxury—they’re a necessity.

MeasureColor’s user-friendly interface is designed to simplify the pressroom experience, putting powerful color science and real-time insights behind a clean, consistent UI that works across workflows. Whether you're managing flexo, offset, or digital presses, MeasureColor helps streamline production planning and empowers operators to make faster, more confident decisions.

Built for today’s pressroom realities, MeasureColor adapts to various print techniques—whether you're working with images, QA targets, or full process control color bars. The interface automatically adjusts to show only the most relevant information for each workflow, eliminating clutter and confusion.

Visual Indicators That Speak Volumes

MeasureColor translates complex color data into simple, intuitive symbols:

- ✅ Green checkmark: Everything is on target.

- ⬆️ Arrow up: Increase ink film thickness.

- ⬇️ Arrow down: Decrease ink film thickness.

- ⚠️ Warning sign: Potential ink recipe issue.

For digital workflows, the “traffic light” view is a game-changer. It helps operators instantly assess whether a correction is minor or requires escalation—saving valuable make-ready time and reducing waste.

All-in-One Control Panel

From dot gain and gray balance to barcode readability and ink zone control, MeasureColor puts everything at your fingertips. Operators can:

- View measurement scores and print run trends

- Export data to ink formulation software

- Create CTP compensation curves

- Monitor visual defects and registration

Touchscreen-Optimized for the Pressroom

Large buttons and icons make MeasureColor ideal for touchscreen use—no keyboard or mouse required. This design choice enhances usability and keeps operators focused on what matters: print quality.

A Smarter Way to Make Color Corrections

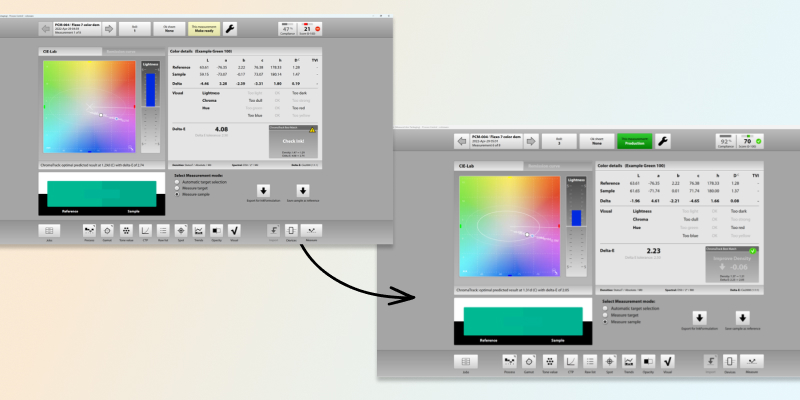

Color correction on press has traditionally involved a lot of trial and error. Operators often rely on DeltaE values to determine color deviation, but these numbers alone don’t tell the full story. Is the color too dark? Too red? Too green? DeltaE can’t answer that.

That’s where MeasureColor’s ChromaTrack technology changes the game. Using a best-match prediction model, it guides operators directly to the right correction—whether it’s a simple density adjustment or a full ink recipe change.

Instead of wasting time and materials, ChromaTrack shows where you are and the shortest path to your color target. Operators can even export measured colors as CxF files and import them into ink formulation software for precise adjustments.

The Result? Higher Efficiency, Lower Costs

With ChromaTrack and the full MeasureColor ecosystem:

- Setup times are faster

- Waste is reduced

- Color consistency improves

- Customer expectations are met or exceeded

It’s a win-win for the pressroom and your bottom line.

Don’t Miss the Rest of the Series

This blog is part of our MeasureColor in Action series—your guide to smarter, more efficient print production. Explore the full lineup:

- #2: MeasureColor: Manage Digital Color Targets with Confidence

Learn how Reference Manager simplifies the organization and application of digital color targets and ICC profiles for consistent results across workflows. - #3: MeasureColor: Optimize Dot Gain for Better Print Quality

See how real-time dot gain monitoring and CTP curve optimization help press operators improve color accuracy, reduce waste, and maintain consistency. - #4: MeasureColor: Maximize White Ink Opacity

Discover how a 3% tweak in white ink opacity can cut ink usage by 33%—and how MeasureColor makes it easy to optimize quality and cost in every print run.

Curious how MeasureColor can optimize your workflow and reduce costly trial-and-error adjustments? Get in touch with our Color Experts today.