Advancing Surface Texture Measurement for Accurate 3D Visualization

In today’s digital design landscape, color and surface texture are inseparable when it comes to accurately visualizing materials. Whether you’re working with textiles, plastics, coatings, or automotive finishes, the way a surface interacts with light—its texture, gloss, and reflectivity—can dramatically alter perceived color and appearance.

Why Surface Texture Matters

Historically, color has been the primary focus of digital material representation. However, as brands and manufacturers strive to replicate the true look and feel of physical products, surface texture has emerged as a critical factor. The way a surface interacts with light—its gloss, roughness, waviness, and microstructure—not only influences perceived color, but also impacts product differentiation, customer satisfaction, and design intent.

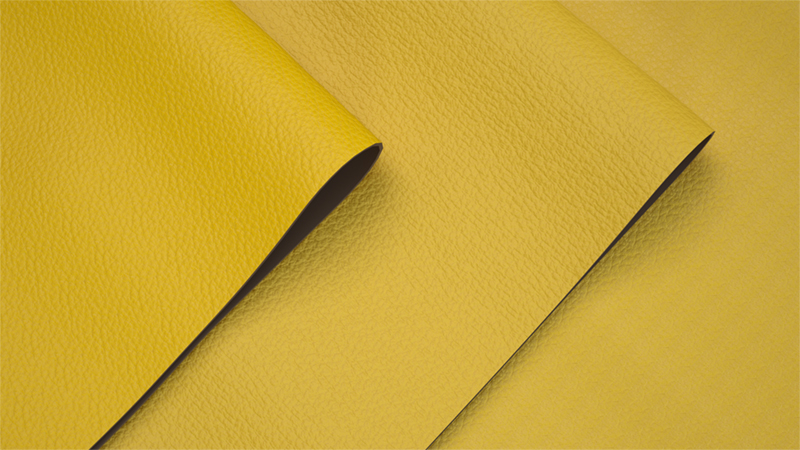

Traditional color measurement tools capture spectral data, but often miss the nuances of surface texture that influence how color is seen. For example, a color on smooth satin appears different than on coarse wool, even if the spectral values match. This is where advanced surface texture measurement becomes essential.

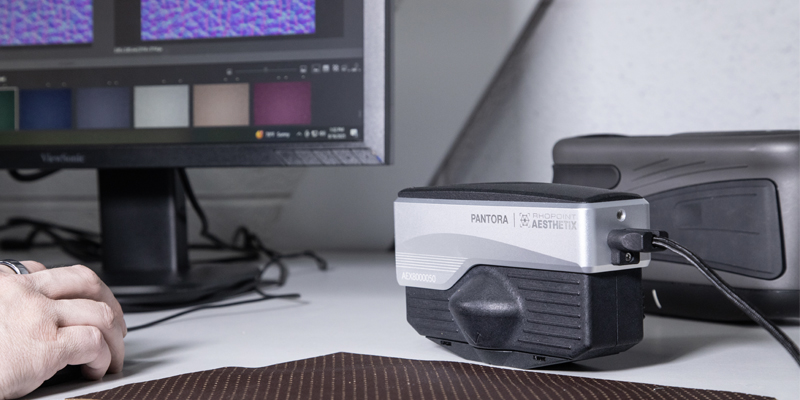

Today, cutting-edge technologies like Rhopoint PANTORA Aesthetix are redefining what’s possible. By combining high-resolution photometric stereo imaging with powerful software integration, these solutions empower designers, material creators, and marketers to achieve a new level of accuracy and realism in digital twins, virtual prototypes, and marketing visuals.

Introducing Rhopoint PANTORA Aesthetix

The Rhopoint PANTORA Aesthetix device sets a new standard for precision in surface texture measurement. Using photometric stereo imaging, it captures multiple images under varied lighting angles to reconstruct a detailed 3D topographical map of the material’s surface. This enables:

- Accurate quantification of texture features such as roughness, waviness, cell size, and amplitude.

- Realistic 3D visualization for digital twins and virtual prototyping.

- Integrated reflectivity and gloss metrics for comprehensive appearance analysis.

How Photometric Stereo Imaging Works

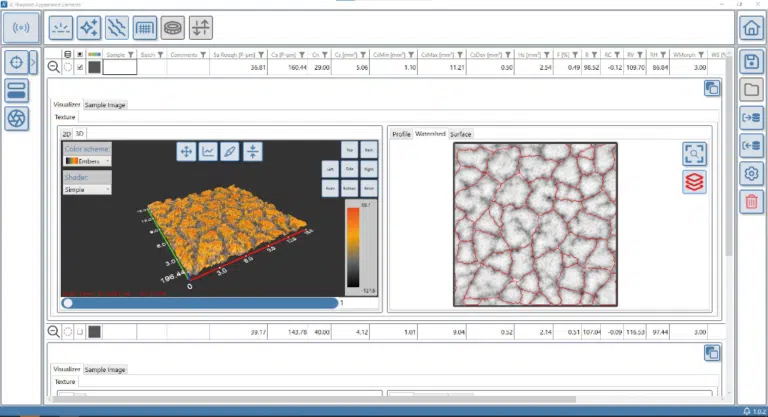

Photometric stereo imaging estimates surface normals and builds a 3D height map by analyzing how light interacts with the material from different angles. The Aesthetix device uses advanced algorithms, such as the watershed method, to segment the surface into distinct cells—quantifying hills, valleys, and other microstructures with exceptional accuracy.

- Higher resolution (110 pixel per mm vs. 40 pixel per mm)

- Larger area of interest

- Correct surface normals for realistic rendering

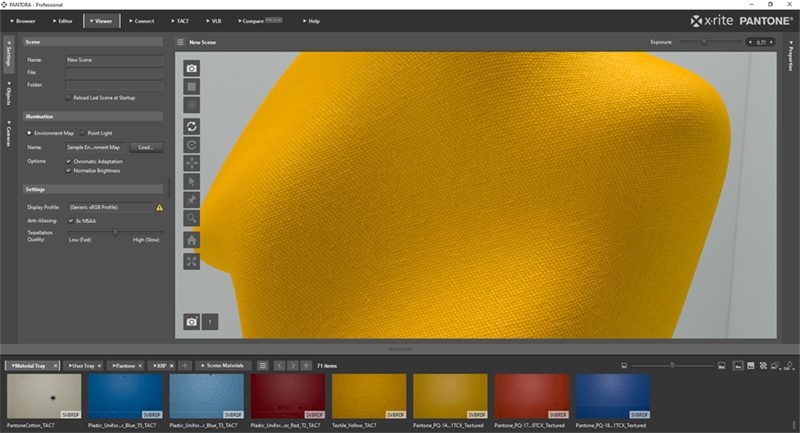

AxF Integration for Enhanced Rendering

The PANTORA software combines texture measurements from Aesthetix with spectral color from X-Rite spectrophotometers, producing high-definition, color-accurate AxF files. This integration reduces the need for more complex measurements and provides best-in-class rendering quality and visual tolerancing.

- Automotive: Interiors

- Plastics: Technical textures, automotive interiors

- Leather: Luxury bags, automotive interiors, furniture

- Paint & Coatings: Kitchen appliances, furniture, polishing

Why Invest in Rhopoint PANTORA Aesthetix Technology

Rhopoint PANTORA Aesthetix delivers transformative benefits for every stage of the digital material workflow:

- High-Definition Digital Material Representation: Create color-accurate, high-definition digital twins that capture texture and special effects for realistic visualization.

- Confidence and Accuracy: Increase confidence that digital materials match real-world appearance, reducing costly errors and rework.

- Efficiency and Speed: Minimize the need for physical samples and photo shoots, accelerating material selection, approval, and time to market.

- Enhanced Communication: Improve collaboration and communication of material properties between suppliers, designers, and brands.

- Marketing and E-Commerce Enablement: Provide highly realistic renderings for marketing and e-commerce, building customer trust and streamlining content creation.

- Applicability Across Personas: Material creators, designers, product developers, and marketers all benefit from more accurate, efficient, and compelling digital workflows.

- Comprehensive Surface Quality Assessment: Assess glossiness, texture, topography, and visual homogeneity for a holistic view of material appearance.

Sustainable and Efficient Workflows

Digitally assessing color and texture before production streamlines development, reduces waste, and supports sustainability goals. Virtual prototypes minimize the need for physical samples, accelerating time-to-market and reducing environmental impact.

To learn more about our Appearance solutions, get in touch with our Color Experts.