One of the many benefits of working closely with our customers is the opportunity to help implement unique and creative color workflows. We share this information with you in our case studies so you can discover how others are managing their color and the impact on their financial success. Whether you’re looking for a hot tip or a new way of managing color, browse our case studies to see what you can learn from companies like yours.

Electric Vehicle Manufacturer Reduces Material Usage of Clay, Foam, and Wood by 2.5 Tons with X-Rite Digital Material Solutions

Explore how an EV manufacturer pioneers sustainability with digital materials, powered by X-Rite’s Appearance Solutions.

Ultimate Textile Case Study

Ultimate Textile was looking for the next generation in handheld devices to ensure the continued delivery of the highest quality dyed fabrics to its customers.

T&N Printing Takes All the Guesswork Out of Color

Read this case study to learn how T&N Printing, a reputable offset printer, has reduced make-ready by 66% by presetting ink keys using IntelliTrax and Rutherford closed-loop system

True Value Enhances Paint Department with MetaVue™

Learn how True Value used MetaVue, a non-contact imaging spectrophotometer, to reduce mis-tints and increase the confidence of paint counter associates for accurately matching paint.

Manufacture d’Histoires des Deux-Ponts

French printer Manufacture d’Histoires des Deux-Ponts adopts closed-loop color control to optimize its offset press.

X-Rite Pantone Helps Perfetti Van Melle Implement a Color Quality Culture and Improve Worldwide Quality Scores by 50%

When it comes to color quality, Perfetti Van Melle turned to X-Rite to help them develop a digital print quality program to achieve brand consistency on shelves around the world.

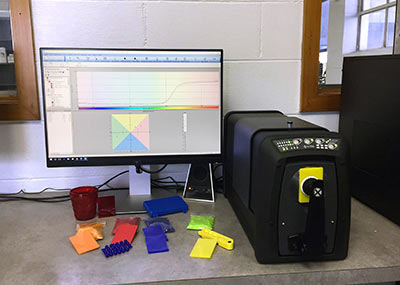

X-Rite Solutions Assist Teknor in Improving Visual Color Evaluation

Teknor, one of the largest privately-owned U.S. plastics companies, established a new Corporate Lab as a shared service to support the company’s color requirements for the creation of color-accurate masterbatches and other products.

Austis Increases Productivity with X-Rite Solutions

Read the story of how Austis a leading manufacturer of water based paints and construction products reduced their color preparation time from one color every two weeks to preparing five or six paint colors per day.

Data-Driven QC for Luxury Watch Parts

Discover how a leading luxury watch manufacturer enhanced their quality control process by implementing the CiF3200 compact spectrophotometer, ensuring precise color consistency for dials, bands, cases, and other small watch parts.

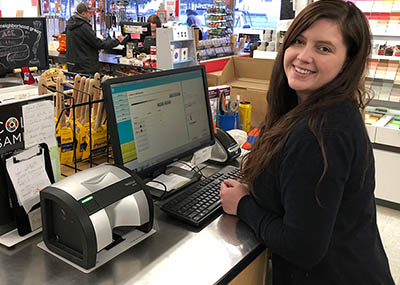

Stayton Ace Hardware Drives Customer Satisfaction with MetaVue™

Learn how MetaVue has helped the paint counter at the Stayton Ace Hardware store make their customer desires a reality, resulting in increased paint revenue and reduced costs due to mistints.

Quality Guaranteed Through Inline Measurement

Smurfit Kappa the market leader in the sustainable development and production of packaging solutions from corrugated cardboard, solid board and carton board, both from fresh fibres and from recycled waste paper.

Plastic Resins Case Study

X-Rite solutions were a critical element that enabled Plastic Resins to efficiently start up operations.

Nail Polish Color As You Imagined It!

Inkk offers a unique service that allows creation of custom nail polish colors to match a color found in a dress, a car or any other inspirational item based on a submitted image.

MetaVue: An Investment with Fast ROI for California Paints

California Paints dramatically improves the process to color perfection with MetaVue, one of the best color measurement instruments they’ve ever seen.

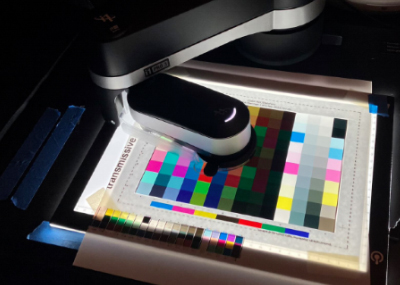

i1Pro 3 Plus and i1iO Enables Primary Color to Expand Color Management to Mesh, Perforated, and Backlit

Primary Color has been reproducing print materials since 1984. Learn how the i1Pro 3 Plus and i1iO enables them to achieve high image quality on backlit material with less manual correction and retouching.

Home Hardware Increases First Time Colour Matches by 80%

Port Stanley Home Hardware used to color match by eye. Since choosing i1 Paint to measure customer samples, paint counter associates are achieving faster, more accurate colour matches.

X-Rite Provides a Leading Packaging Manufacturer with an Integrated Color Workflow for Streamlined Success

Learn how a leading packaging manufacturer transformed color evaluation from a subjective visual process into an integrated and connected color workflow for improved color accuracy.

Home Hardware Reimagined Paint Color Matching with MetaVue™

Learn how a Home Hardware store used MetaVue to measure the most difficult paint matching samples with 50% more accuracy and ease of use than other models.

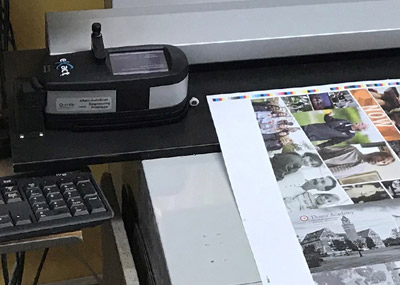

X-Rite eXact Auto-Scan Helps J&R Graphics Work “Faster, Better, Cheaper, Period.”

J&R Graphic added the eXact Auto-Scan to their workflow and cut their make ready in half!

Evaluating Special Effect Colors with a Multi-Angle Spectrophotometer

Advances in special effect technology are changing the way quality control managers evaluate and control color. Learn why a multi-angle spectrophotometer is the right tool for the job.

Enerplastics

Discover how Enerplastics increased quality, consistency and accuracy in Masterbatch colors while managing more than 20,000 colorant recipes.

Diamond Vogel Improves Color Match Accuracy by 65%

X-Rite MetaVue helps Diamond Vogel formulators spend less time training, more time formulating, and has already reduced waste by 35% in just 18 months.

Soap & Glory Uses X-Rite Digital Solutions for Color Success

Read how X-Rite's digital color solutions enabled No7 Beauty Company to set clear color expectations for Soap & Glory packaging across the supply chain.

PantoneLIVE and ColorCert support Dongguan Modern Paper Company to Streamline Production and Achieve Faster Color Matching

With a focus on sustainability, Dongguan Modern Paper found a way to achieve fast, accurate color to streamline production and minimize waste for their production facilities and customers.