If you work in the print and packaging industry, standards can help you set clear expectations for clients, solve problems in your workflow, and improve productivity. They can also bring an independent perspective to production.

If you work in the print and packaging industry, standards can help you set clear expectations for clients, solve problems in your workflow, and improve productivity. They can also bring an independent perspective to production.

Printers aren’t the only ones who should keep up with standards. Brands who are concerned with quality, price, and speed to market can also benefit because it allows them to compare print providers and choose the best candidate.

The ISO and other standards organizations have been very busy trying to address the new technology challenges that printers face. Here is some insight about what’s new in the world of graphic arts standards and technical specifications so you can take advantage of them in your print and packaging workflow.

Changes for Traditional Analog Print

In print production, there are a couple of things coming up in the next year that aren’t necessarily new, but impactful. 12647-2 is the granddaddy of many standards and processes used for commercial offset print. Currently in revision, the committee is working on incorporating the near neutral methodology from CGATS TR015 (think G7 from Idealliance) into the next version along with updates to the traditional TVI approach.

Standards tend to have a 5-10 year lifecycle, and a lot of things have changed in print, print production, papers, materials, etc., which all feed into this standard. If you have ideas for commercial print changes that you think could improve ISO 12647-2, now is the time to share them. Get in touch with a standards organization so your voice can be heard.

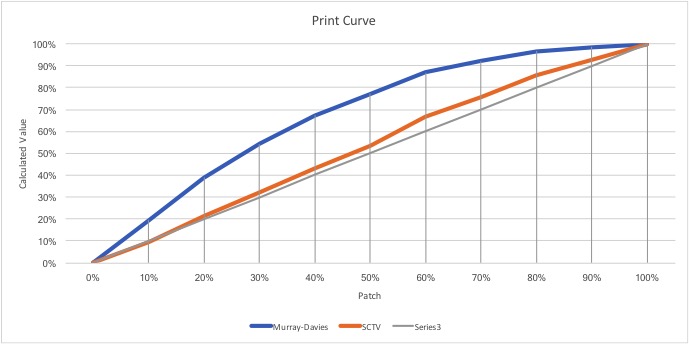

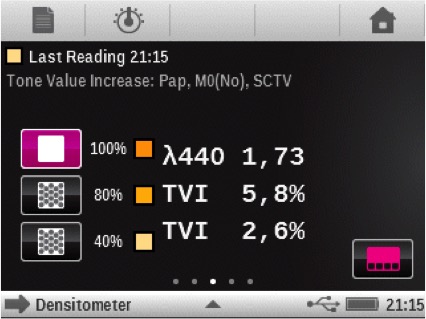

12647-6 is a similar standard for the flexo print process. It has been a really solid standard, but has a slightly different twist because it’s mostly colorimetry. A big change is the addition of SCTV – Spot Color Tone Value. This is a new way to calculate tone value for spot color; SCTV replicates what you see as opposed to the more arbitrary tone value numbers we are used to working with when evaluating process color. There will be other changes to the flexo spec as well, but this is the biggest.

SCTV and Murray Davies curves for orange

SCTV in eXact

Somewhat related to the above news is the new CGATS characterization target data set: IT8.7/5 - Graphic technology - Input data for characterization of 4-color process printing. This incorporates elements for enhanced gray balance and patches used for G7 calibrations. The next step is moving this to ISO, which is already in progress.

A great overview of which ISO standards impact you can be found in ISO TR 19305 Graphic Arts Workflows which shows stakeholders, their responsibilities and what standards apply to them.

Changes for Digital Print

There are also a lot of new things happening in digital print this year, as you’d probably expect. But unlike analog print, we don’t want to go to the ISO standard path yet because things change quickly. Instead, we’re developing a technical specification, which allows for faster and more frequent revisions.

15301 is a relatively new series of documents that mostly focuses on digital print, but can also be used in analog. Part 1 defines new tests that are more focused on digital, offering printers a more concrete way to compare work, and form the basis for tests used in other parts of the series

Part 2 is focused on digital production print and helps companies compare their output in an objective way. This is a huge difference because potential clients can compare apples to apples when evaluating both printer technologies and print providers, instead of the subjectivity that results from everyone each conducting their own unique tests

Although this specification is focused on digital, it can be applied to analog. Most printers aren’t starting new digital workflows, but instead are enhancing their existing processes. By conducting these tests on their analog processes, printers can find out if they’re over-specifying the digital side when they can really achieve the same quality in analog.

Another big growing part of digital is wide format. We’ll move down that path once it is more established.

Ways You Can Stay Current

Keeping current with standards is a tricky job because standards are always changing. It really becomes a question of how to get informed, and how to stay informed.

One way is to be part of the process. If you have expertise in a particular area, there’s probably a standards or specifications working group for it that could be improved with your expertise, plus give you a lot of insight into the process.

Another way is to work with one of the specification groups. For example, if you are a flexo printer working in a packaging workflow, being part of the Flexographic Technical Association (FTA) would give you a lot of insight into applicable standards. If you’re in commercial printing, someone like Idealliance or Fogra can give you input into that process, and maybe even additional insight into how the standards are being implemented in your geography or within your brand users.