Top Manufacturing Trends in 2025

The manufacturing industry is undergoing a seismic shift in 2025, driven by rapid technological innovation, sustainability imperatives, and the need for greater agility. As manufacturers adapt to these changes, color accuracy and quality control remain critical to maintaining brand integrity, reducing waste, and meeting customer expectations. At X-Rite, we’re uniquely positioned to help manufacturers navigate these trends with confidence.

According to industry experts, here are the key trends shaping manufacturing this year:

- Generative AI and Smart Automation

Manufacturers are leveraging generative AI to optimize product design and production processes. Smart robots and AI-driven systems are enhancing efficiency and enabling mass customization. - Digital Transformation and Industry 4.0

The integration of IoT, cloud computing, and digital twins is transforming factories into intelligent, connected ecosystems. Predictive maintenance, real-time analytics, and automated workflows are becoming standard. - Sustainable Manufacturing

With growing regulatory and consumer pressure, manufacturers are adopting circular economy principles, reducing emissions, and minimizing material waste. - Data-Driven Quality Control

Precision and consistency are non-negotiable. Manufacturers are investing in advanced quality control systems to ensure product uniformity and reduce costly rework. - Human-Machine Collaboration

The rise of “cobots” (collaborative robots) and AI-enhanced tools is reshaping workforce dynamics, requiring new skills and seamless human-machine interaction.

How X-Rite Supports These Trends

X-Rite’s solutions are at the intersection of color science, digital transformation, and quality assurance. Here’s how we help manufacturers align with 2025’s biggest trends:

- Enabling Digital Transformation with Connected Color Workflows

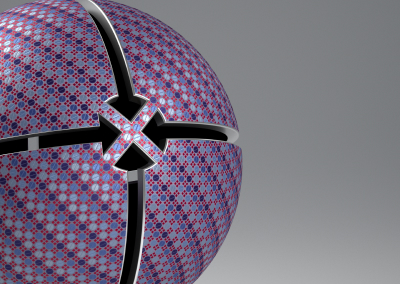

Our cloud-based platforms and integrated software solutions allow manufacturers to digitize and streamline their color workflows—from design to production. With tools like PantoneLIVE and Color iQC, teams can collaborate globally, reduce approval cycles, and ensure color consistency across the supply chain. These platforms help build and maintain centralized color data repositories that support AI-driven analytics and predictive quality control. - Creating Digital Material Twins with PANTORA

As manufacturers embrace digital twins and virtual prototyping, PANTORA plays a critical role in creating accurate digital representations of physical materials. By capturing spectral data and surface appearance with a spectrophotometer, PANTORA enables the creation of digital material twins that can be used in design simulations, virtual renderings, and automated quality checks. This supports the broader Industry 4.0 vision of connected intelligent manufacturing ecosystems.

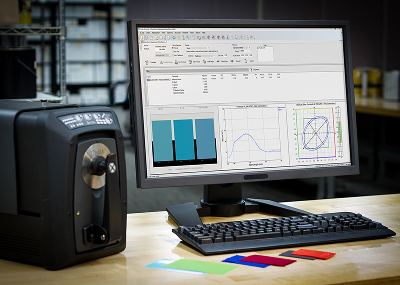

- Supporting Smart Manufacturing with Real-Time Color Data

X-Rite’s inline color measurement systems, such as the ColorXRA 45, provide real-time data for process control. These tools integrate seamlessly with MES and IoT platforms, enabling predictive quality control and reducing downtime. By optimizing color data collection and analysis, manufacturers can respond quickly to deviations and maintain high standards. - Advancing Sustainability Through Waste Reduction

Accurate color measurement reduces the need for rework and excess sampling, minimizing material waste. Our solutions help manufacturers meet sustainability goals by improving first-time-right production rates and reducing energy consumption. Optimized color data ensures that every production run meets specifications, reducing scrap and environmental impact. - Enhancing Quality Control with Precision Instruments

From benchtop spectrophotometers to portable devices, X-Rite offers a full suite of tools to ensure color accuracy across materials and surfaces. Our instruments support ISO and industry-specific standards, helping manufacturers maintain compliance and brand consistency. These tools also help maintain long-term color data integrity, supporting traceability and continuous improvement.

- Empowering the Workforce with Training and Support

As manufacturing evolves, so must the workforce. X-Rite provides training, certification, and ongoing support to help teams master color science and integrate new technologies effectively. Our educational resources help teams build foundational knowledge and stay current with best practices in digital color management.

Conclusion: Future-Proofing Manufacturing with X-Rite

In 2025, success in manufacturing hinges on agility, precision, and innovation. X-Rite empowers manufacturers to embrace digital transformation, enhance quality, and drive sustainability—without compromising on color accuracy. Whether you're producing automotive parts, packaging, textiles, or electronics, our solutions ensure your products look exactly as intended, every time.

Ready to align your operations with the future of manufacturing?

Let’s talk about how X-Rite can help you lead with color confidence.