Why Accurate Color is Critical

Per the 90/90 Rule of Color, consumers make snap judgments about products when they first interact with them at the shelf or in the showroom. Color sends a brand message and helps differentiate products from competitors. It also sends a message about freshness – faded colors make products and packaging look old and may discourage a buying decision.

That’s why maintaining accurate color throughout the manufacturing process is so critical. It makes life in production and quality control easier and makes customers happier. It leads to reduced waste and rework as well as consumer rejection.

The first step in assuring accurate color is understanding how good your color vision is. Use the Farnsworth Munsell 100 Hue Test to find out. It is easy to administer and a highly effective method for measuring an individual’s color vision.

The next step is visual evaluation. Read the 5 tips the best color companies use in evaluating color visually.

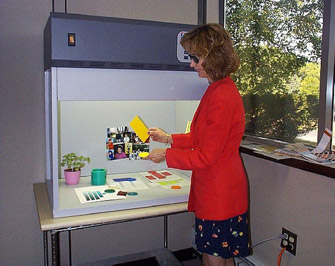

- Choose the correct lighting condition. Use a light booth to evaluate samples using every light source under which the final product will be seen.

- Minimize surrounding light. The only light in the room should be coming from within the light booth. Light is color, and even a little bit streaming through the window or from a table lamp can change the color perception of your sample.

- Look fast. You may think that staring will help you focus, but our eyes actually become less sensitive after 5-10 seconds of looking at the same object. When judging color, look fast, then rest your eyes before you judge again.

- Properly arrange your samples. Place the sample on the bottom of the booth, parallel to the light source. If you’re comparing samples, lay them side-by-side so they’re parallel and touching. Even a slight space between colors can trick your eyes.

- Beware of metamerism. Metamerism is a phenomenon that occurs when objects match in one light source, but not another. It commonly occurs when dyes, paints or pigments are changed during production. To check for metamerism, view your samples under a variety of different light sources.

What’s wrong with this picture? Pretty much everything!

Talk to one of our Color Experts today to learn how you can ensure perfect color throughout the manufacturing process and make your life easier.