Discover the Unified My X-Rite Portal: One Platform for All Customers At X-Rite, our mission has always been to make it simple, seamless, and efficient for you to manage your devices, software, and services. With the My X-Rite online portal, we’ve already taken major steps to give you one place to handle service requests, track orders, and access important product information. Now, we’re excited to share the next big evolution: merging X-Rite Link and My X-Rite into a single...

X-Rite Video Gallery- Your Ultimate Resource for Color Education Welcome to the X-Rite Video Gallery Whether you're a novice or an experienced professional, the X-Rite Video Gallery offers in-depth color education and practical training to enhance your color management skills. Our carefully curated collection of videos provides valuable insights and expert tips designed to help you master color accuracy and optimize your workflow. In this blog, we'll highlight five must-watch videos that sho...

Per ottenere una misurazione del colore precisa e coerente, è essenziale investire in uno spettrofotometro di alta qualità. Gli spettrofotometri sono fondamentali per la qualità del colore perché forniscono dati ripetibili e affidabili che garantiscono la conformità dei prodotti a rigorosi standard cromatici. Che si tratti di produzione di beni durevoli, abbigliamento, cosmetici o materiali per l'edilizia, lo spettrofotometro giusto può fare la differen...

Abbracciare soluzioni ecologiche per un domani più radioso In un mondo in rapida evoluzione come quello odierno, la sostenibilità è diventata un aspetto cruciale per i produttori di diversi settori. Con l'aumento della consapevolezza ambientale dei consumatori, è cresciuta la domanda di pratiche sostenibili nella produzione. Questo spostamento verso la sostenibilità non solo porta benefici al pianeta, ma migliora anche le operazioni aziendali, portando a...

L'esigenza di standard di settore per la valutazione visiva del colore con l'illuminazione a LED in ambito retail Nel settore retail, l'illuminazione è un fattore critico che influenza la percezione dei prodotti da parte dei clienti. Tuttavia, la mancanza di standard per l'illuminazione a LED pone sfide significative che possono avere un impatto sia sui rivenditori che sui consumatori. Riproduzione del colore incoerente Uno dei problemi principali dell'assenza di standard per l'illumin...

Perché la retrocompatibilità degli spettrofotometri è fondamentale per un colore coerente Se sei arrivato fin qui, è probabile che utilizzi uno spettrofotometro da banco per avere sempre una qualità del colore ottimale. Da tessuti e plastica a vernici, rivestimenti e altro ancora, questi strumenti di alta precisione sono fondamentali per mantenere l'uniformità nei tuoi processi. In X-Rite, progettiamo spettrofotometri per garantire prestazioni affidabili...

Sei alla ricerca di una sede centrale per gestire i prodotti e servizi X-Rite? Dai un’occhiata a My X-Rite. Il nostro portale online gratuito è raggiungibile con pochi clic per darti tutto quello che cerchi: assistenza e informazioni sul prodotto, dettagli sui servizi e accesso alle risorse di apprendimento. Accesso 24/7: per accedere facilmente alla tua dashboard personale direttamente dal computer o dispositivo mobile, 24 ore su 24. Dashboard personalizzata: guarda que...

In the sign and display graphics business, as in many other segments of the printing industry, shorter runs and reduced cycle times can stress even the most efficient wide format printing operations. By implementing a color-managed RIP-to-roll (or RIP-to-rigid media) workflow, these operations can ensure that color is right the first time and every time to help speed work through the shop and meet color expectations. Photo by Peter Saunders Today we are share tips from our Color Experts that c...

Cosa succede se devi gestire più di 2.000 colori dei brand in una complessa filiera di produzione globale del packaging? Le cose si fanno complicate! Anche se al momento può sembrare più facile creare un nuovo colore che cercare nei database o nei raccoglitori di drawdown per trovare la migliore corrispondenza, il problema si ha in seguito, quando ti ritrovi con una libreria enorme, ingestibile. Uno dei nostri clienti, una nota azienda del settore FMCG (beni di largo consum...

Does your quality control program include visual evaluation? If not, it should. Using the SpectraLight QC as part of a color evaluation workflow. No matter your industry, judging color is more than just measuring samples with a color measurement device. Just because a spectrophotometer says your color is within tolerance, doesn’t necessarily mean it will look right to the human eye. To minimize customer rejects, your color control process needs to include visual evaluation in a light boo...

In questo periodo dell’anno, Internet riporta in abbondanza elenchi di top 10. Una tradizione accolta sin dal 1940, quando Billboard pubblicò la prima classifica dei dischi più venduti. Da allora, in molti hanno iniziato a pubblicare classifiche analoghe, per evidenziare le tendenze più popolari dell’anno precedente. Dal 2016 pubblichiamo la classifica dei post più letti nel nostro blog, e siamo lieti di vedere che ogni anno, nelle prime posizioni...

It’s important to ensure design intent is realized each time and everywhere a product appears. But with so many variables to impact print quality, how can brands utilize suppliers around the world and still achieve consistent color? Our X-Rite Pantone Packaging Color Experts have designed a series of consulting services and workshops to help you get the most from your print, packaging, plastic or textile value chain. Offered both online and onsite, these interactive sessions i...

Sostieni che il colore è importante, ma ne conosci a fondo importanza? In realtà, il colore è un elemento fondamentale nel processo di produzione. Oggi, molti produttori si rendono conto che ottenere il colore esatto è molto più complicato di quanto fosse in passato, e ricevono richieste di tolleranze più rigorose dai brand owner che supportano. Ecco perché. Se i progressi nella tecnologia del colore – p.e., packaging metallici, finiture pe...

I clienti alle prime armi in materia di gestione del colore spesso ci domandano: "Qual è la differenza tra uno spettrometro e uno spettrofotometro?". Dal punto di vista ortografico, la differenza è minima ed è, quindi, facile confondersi e ottenere la risposta sbagliata a questa domanda. E allora, qual è la differenza? Spettrometri e spettrofotometri a confronto Cos'è uno spettrofotometro? Uno spettrofotometro è un dispositivo di misurazion...

Quante prove ed errori vi occorrono per formulare un colore? Se la risposta è più di tre, potrebbe essere il momento di ricorrere all'aiuto di una soluzione computerizzata. La formulazione del colore assistita dal computer può portare enormi vantaggi alla vostra attività. Anche i principianti possono raggiungere più rapidamente gli obiettivi cromatici, risparmiando tempo, denaro e coloranti costosi. Una volta stabilito un metodo accurato, potete aspettarvi di s...

Con un numero sempre maggiore di marchi di beni di consumo (CPG) che implementano programmi di controllo della qualità degli imballaggi per monitorare le tolleranze cromatiche, i trasformatori e gli stampatori di imballaggi hanno bisogno di soluzioni di misurazione del colore che si integrino direttamente con i sistemi di reporting. Le nostre soluzioni di scansione IntelliTrax2 Pro e eXact Auto-Scan Pro combinano la potenza dei nostri dispositivi di scansione automatica leader del settore con la...

X-Rite acquired GretagMacbeth in 2006, making most GretagMacbeth handheld and benchtop spectrophotometers 20+ years old. If you're still using one of these legacy spectrophotometers and color consistency is important to your business, we encourage you to consider upgrading to a new, ISO-certified X-Rite device for the best experience. Here at X-Rite, we continue to research and improve our color measurement technology so our customers can meet tighter color control tolerances. Improved color mea...

In un mondo ideale, dovresti poter installare gli inchiostri sulla macchina da stampa ed eseguire il lavoro. Sfortunatamente, ogni anno i laboratori di stampa rotocalco e flessografica sprecano inchiostro, substrati e tempo cercando di ottenere i colori giusti. Nonostante sia più facile ottenere colori precisi grazie ai progressi tecnologici, ci sono ancora variabili che influiscono sul colore.

In questa serie in tre parti, ti forniamo più di due dozzine di motivi per cui il colore potrebbe non essere giusto in macchina. Leggi il primo articolo dedicato agli strumenti se te lo sei perso.

Oggi vediamo come standard e inchiostri possono influire sul colore finale.

1 - Utilizzo dello standard cromatico sbagliato.

È facile selezionare lo standard cromatico sbagliato nel software. Alcuni sistemi hanno centinaia, se non migliaia, di standard cromatici. Ecco qualche consiglio:

- Assicurati che lo standard che selezioni abbia le stesse caratteristiche del lavoro che stai stampando.

- Organizza gli standard per cliente e includi informazioni come substrato, cilindro retinato, sistema di inchiostri, ecc.

- Immetti lo standard con le impostazioni corrette per lo strumento e il materiale di supporto.

- Assicurati che lo standard cromatico sia sullo stesso materiale del campione di stampa. Ad esempio, non puoi confrontare un colore Pantone non patinato su materiale bianco imbianchito con lo stesso colore su materiale ondulato bianco KLA chiazzato biancastro.

2 - Utilizzo di troppi coloranti.

Un lotto di inchiostro formulato usando troppi coloranti potrebbe non essere in grado di darti il colore o l'intensità che desideri. Questo causa in genere uno scenario del "serpente che si mangia la coda" perché i rapporti dei coloranti sono diversi uno dall'altro. Formula sempre gli inchiostri usando il minor numero di ingredienti possibile.

3 - Cambio di substrato.

Il substrato in macchina è esattamente lo stesso del substrato usato per creare lo standard? Il fornitore del substrato ha difficoltà a fornirti materiali coerenti? Il materiale è laminato con un materiale diverso da quello di ieri? Stai confrontando una struttura laminata usando poliestere opaco invece di trasparente?

Il cambio di substrato può influire molto su come il colore viene letto in macchina. È consigliabile rendere i substrati dei veri e propri standard nel workflow, proprio come i drawdown. E prima di controllare i colori, controlla il substrato per assicurarti che rientri nei limiti di tolleranza prima di eseguire il viraggio degli inchiostri o eseguire il lavoro.

4 - Trascurare la vernice per sovrastampa.

La vernice per sovrastampa (OPV) viene spesso trascurata perché è trasparente, ma non lasciarti ingannare. La vernice per sovrastampa può influire notevolmente sulla variazione del colore. In genere, la vernice per sovrastampa fa tendere il colore verso il blu. Può anche farlo apparire più scuro e intenso.

Con la maggior parte dei colori, noterai un calo del valore L quando applichi la vernice. Se non sei sicuro, esegui qualche lettura con e senza vernice per sovrastampa per vedere la differenza. Se il lavoro richiede l'applicazione di vernice per sovrastampa, è consigliabile immettere lo standard cromatico con vernice per sovrastampa poiché questo è il risultato finale che vedrà il cliente. La vernice per sovrastampa può anche causare problemi quando passa attraverso il centro di una barra colore. Poiché alcune letture includeranno la vernice mentre altre no, avrai letture irregolari.

5 - Uso di un lotto di inchiostro di scarsa qualità.

Anche al migliore tecnico degli inchiostri può capitare un lotto di inchiostro scadente. Ma se non scopri subito il problema, ti potrebbe costare sprechi in macchina e numerose ore per eseguire il viraggio dell'inchiostro. Un modo per risolvere questo problema è quello di definire un programma di controllo qualità in sala inchiostri per assicurarti che arrivino gli inchiostri corretti alla macchina. Una pratica comune è quella di allegare un certificato di analisi ai lotti inviati alla macchina per garantirne la precisione. Dovresti anche misurare e convalidare gli inchiostri prima di installarli sulla macchina.

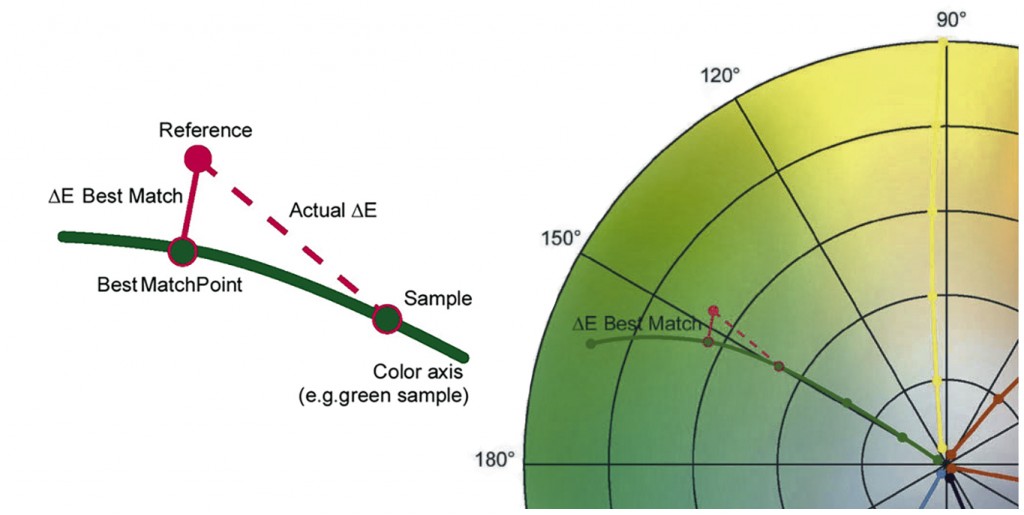

La funzione BestMatch di eXact è uno strumento predittivo per il colore che valuta la concentrazione e lo spessore dell'inchiostro per determinare se si può ottenere il colore corretto. Aiuta anche a determinare se si può ottenere una migliora corrispondenza con un colore specifico regolando l'inchiostro in macchina. Dai un'occhiata al nostro blog Bringing Ink Back into Tolerance per saperne di più.

6 - Contaminazione.

Questo è un problema comune nelle sale stampa che lavorano a pieno regime. Gli operatori delle macchine da stampa, in particolare se si impiegano inchiostri a base solvente e base acqua, devono usare additivi quali stabilizzatori, glicole, alcohol, acqua, ecc. per mantenere le prestazioni dell'inchiostro. Troppi additivi possono tuttavia rovinare l'inchiostro. Quando tutti lavorano in fretta per portare a termine un lavoro, succede spesso di non pulire accuratamente i circuiti e le coppe della macchina da stampa quando si cambiano i colori.

Una volta che un colore è contaminato, l'unico modo per risolvere il problema è iniziare tutto da capo. Lo strumento Basic Compare di eXact 2 è in grado di confrontare l'inchiostro in macchina con l'inchiostro di un flacone nuovo per verificarne la contaminazione. Un modo meno scientifico consiste nel versare un po' di inchiostro della macchina sul coperchio del flacone originale. Se riscontri un notevole differenza tra i due, la probabilità che l'inchiostro sia contaminato è alta.

7 - Asciugatura non corretta.

Gli inchiostri che non si asciugano correttamente possono causare la riumidificazione. Ciò potrebbe influire o meno sul colore, ma è importante esserne consapevoli. In un caso limite, la coppa del giallo di quadricromia può diventare completamente arancione o persino marrone se gli altri inchiostri non si asciugano correttamente.

8 - Opacità diverse.

Colori di inchiostro diversi hanno opacità diverse. Le cose si complicano ulteriormente perché le aziende produttrici di inchiostri usano svariati sistemi di inchiostri e decine di fornitori, creando infinite possibilità in fatto di variazione dell'opacità. eXact 2 Plus di X-Rite supporta la lettura dell'opacità.

Per evitare di sprecare tempo e denaro, esegui la lettura dell'opacità. Se conosci le diverse opacità puoi definire aspettative realistiche per i clienti.

A seguire...

Come menzionato nella prima parte di questa serie, non otterrai colori uniformi se un solo operatore segue questi consigli. Devi documentare tutto e comunicarlo a tutte le persone coinvolte nel workflow.

Dai un'occhiata all'ultima parte della nostra serie " Perché il colore potrebbe non essere giusto in macchina" - Fattori ambientali e legati alla macchina da stampa.

Soluzioni di gestione del colore descritte

Per saperne di più sui prodotti descritti:

X-Rite eXact 2: con funzionalità innovative come la tecnologia brevettata di target video Mantis, unica nel suo genere, e la tecnologia zoom Digital Loupe, eXact 2 è la scelta ideale per stampatori, converter e fornitori di inchiostri.

eXact Auto-Scan: soluzione di scansione integrata nella macchina da stampa che fornisce agli stampatori di piccole e medie dimensioni il feedback immediato sulle prestazioni con conformità agli standard G7 e una migliore funzionalità di creazione di report sul controllo qualità.

IntelliTrax2: soluzione di scansione integrata nella macchina da stampa che fornisce agli stampatori commerciali e su cartone pieghevole di medie e grandi dimensioni il feedback immediato sulle prestazioni con conformità agli standard G7 e una migliore funzionalità di creazione di report sul controllo qualità.

Ci64: lo spettrofotometro a sfera portatile più preciso di X-Rite, disponibile in tre modelli con misurazioni Gloss correlato, SPIN/SPEX simultanee e un'opzione UV.

InkFormulation Software: il software InkFormulation è una soluzione rapida, precisa e coerente di formulazione dell'inchiostro, nonché di creazione, archiviazione, approvazione e reperimento di formule per inchiostri di stampa offset, flessografica, rotocalco e serigrafica.

Pe

In un mondo perfetto, si dovrebbe essere in grado di mettere l'inchiostro nella macchina da stampa, eseguire un lavoro e ottenere l'uniformità del colore. Purtroppo, ogni anno le operazioni di stampa flessografica e rotocalco sprecano inchiostro, substrato e tempo di stampa nel tentativo di ottenere il colore giusto. Sebbene i progressi della tecnologia abbiano reso più facile ottenere l'accuratezza del colore, le variabili che influiscono sul colore esistono ancora. In questa serie di tre pa...

In un mondo ideale, dovresti poter installare gli inchiostri sulla macchina da stampa ed eseguire il lavoro. Sfortunatamente, ogni anno i laboratori di stampa rotocalco e flessografica sprecano inchiostro, substrati e tempo cercando di ottenere i colori giusti. Nonostante sia più facile ottenere colori precisi grazie ai progressi tecnologici, ci sono ancora variabili che influiscono sul colore. In questa serie in tre parti, ti forniamo più di due dozzine di motivi per cui il colore...

.jpeg?h=285&iar=0&w=400&hash=0523DB2B1F04DDB749857624F89F0163)