Are your customers rejecting shipments due to incorrect color? Are you identifying color issues during quality control? If your bottom line depends on color accuracy, you need to ensure your spectrophotometer is not the cause.

Color drift is a big issue for a lot of companies. Even worse, many don’t even know it’s happening. Here are some ways to make sure your spectrophotometer is operating within specification to always capture accurate and consistent measurement data.

Causes of Spectrophotometer Color Drift

All spectrophotometer brands, makes, and models are susceptible to drift. No device, no matter the cost or the manufacturer, is exempt, but there are things you can do to ensure yours keeps working in “just from the factory” condition.

1. Maintain and calibrate your spectrophotometer.

X-Rite’s color measurement devices are built to last, but you must take care of them. Here are some tips to keep yours in tip-top shape.

First, keep your device clean. Measuring with a dirty device is like driving with a cloudy windshield…not recommended if you want accurate and consistent readings. Your spectrophotometer’s user manual includes best practices for cleaning the aperture, white tile, and other components. Follow them carefully because cleaning your device in the wrong way could void your warranty. A good rule of thumb is to never use anything harsh or abrasive in the cleaning process. (Can’t find your X-Rite user manual? Most can be found by searching for your device on www.xrite.com. If you can’t find yours, contact casupport@xrite.com)

How often you clean your device depends on your environment. If you use it in a factory with airborne contaminants, you should probably clean it daily. If you work in an air-conditioned office, you may get by with weekly, or even monthly, cleanings.

A spectrophotometer may drift between calibrations because of multiple factors, including temperature, light source and photo detector. Since wavelength calibration eliminates these drift factors, you should calibrate each time you start a job and at least once a day to bring your device back to its original factory settings. The longer you go without calibrating, the harder it will be for your device to bring itself back into a calibrated state.

If you own a Ci7000 series benchtop, you may find these videos helpful:

- How to Maintain your Sphere Geometry Instrument

- How To Calibrate for Transmittance Measurements

- How To Calibrate for Reflectance Measurements

2. Certify your spectrophotometer annually.

The measurement accuracy of your spectrophotometer can drift over time due to age, wear, and environmental conditions. Factory ISO certification will give you – and your customers – confidence that your instrument is capturing accurate spectral data. Annual certification can also help you win new business - many brands require proof of certification when choosing a supplier.

As an ISO:9001 certified and ISO:17025 accredited business, X-Rite meets the quality and regulatory requirements to certify your device to ISO standards. We recommend factory certification once a year. When you send your device to us, an X-Rite certified technician will verify and document your device’s incoming performance, inspect and clean it, test measurement accuracy, and verify its repeatability and consistency. Your device will come back to you with a dated sticker or paper certification of NIST traceability to standard white.

Our Service Centers and Global Certified Partner Sites feature our most advanced testing capabilities, including temperature and humidity-controlled service areas. Our streamlined operations ensure that you will get your device back as quickly as possible. To certify your device, you can send it into one of our 11 service centers or 45 service partner locations around the world or request we come to you for onsite field service. Learn more.

3. If you use more than one spectrophotometer, verify they are measuring consistently.

If each spectrophotometer in your fleet measures a little differently, your readings – and production output – will reflect this color difference. Using a tool like NetProfiler to check wavelength errors and adjust and validate instrument performance on a monthly basis.

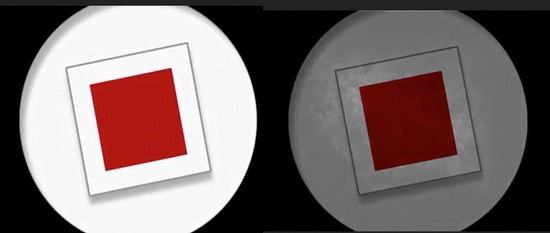

NetProfiler is a cloud-based blend of software and ceramic tile color standards to adjust and validate spectrophotometer performance and reduce variation between devices. As instruments drift over time due to extended use or changing environmental conditions like temperature and humidity, NetProfiler will make automatic adjustments to ensure you are always getting accurate measurements. It can also be used to reduce variation between devices and will inform you when the instrument needs service before it results in off color products.

Many of our instruments have embedded NetProfiler status lights to verify the device is optimized before each measurement. You can learn more about the benefits of using NetProfiler with our Ci7000 Series of sphere benchtops here.

4. Replace legacy spectrophotometers.

If your instrument is old and no longer supported by the manufacturer, it cannot be certified and should be replaced. To upgrade your legacy device to a new, certified instrument, check out our current promotions.

5. Ensure your spectrophotometer is expertly maintained with a Service Care Plan.

X-Rite Service Care Plans ensure your device continues to operate at peak performance to improve reliability and increase the lifespan. Available as one-, two-, or three-year options, our Service Care Plans provide additional protection beyond the product defect coverage of a basic warranty so you can avoid costly surprise breakdowns and plan for the future with predictable maintenance budgets.

We offer a variety of Service Care Plans to choose from to help you get the most from your investment and maintain your certifications. Watch our partner video and learn more about our Service Care Plans here.

Other Causes of Color Drift

Your spectrophotometer is only one of many potential causes of color drifts. Read my recent article published by Quality Digest to learn about other things to look for, or get in touch for help from one of our Color Experts.