To establish a successful quality control program, you need good instrumentation, robust software, and trained users. But even with everything in place, there are some common pitfalls to watch for when using a spectrophotometer to analyze color quality.

Measuring plastic parts with the X-Rite Ci7800 benchtop spectrophotometer.

Top Five Color Measurement Pitfalls

1. Bad Standards and Samples

Physical standards and samples don’t last forever. Careless handling and dirty devices can quickly destroy them. Here are three tips to avoid bad sample:

- When creating a physical standard, gather multiple samples from the same batch and verify the samples are the same shade. If a working standard becomes damaged, you can just throw it away and replace it with a backup.

- Standardize, document, and communicate your sample preparation procedures to everyone involved in the workflow to ensure that each user does each task the same way, every time.

- Keep your samples clean. Dust, oil and fingerprints can cause inaccurate measurement data. Our guide to caring for physical samples offers tips to preserve your samples and standards.

- Extend the life of your standards by storing them in a black plastic bag (without plasticizers) or in non-acidic paper envelopes in a cool, dark place. Refrigerators and freezers will also extend sample life.

2. Optical Brighteners

White isn’t always what it seems to be. This effect is caused by the presence of optical brighteners, which are fluorescent materials that manufacturers add to make their products look whiter.

Here we have two white shirts. The fabrics look identical under daylight, but the whites are quite different when viewed under UV lighting. This can be a real problem for manufacturers who assemble products with parts from different factories. It’s pretty obvious these shirts were sewn together with fabric from different suppliers.

Here are three tips to control optical brighteners:

- Use a lightbooth to inspect raw materials under multiple lighting conditions so you can identify an issue before production or assembly.

- Use a lightbooth to inspect finished products, too. Catching an issue now is still less expensive than after shipment.

- Use a spectrophotometer that is capable of capturing UV measurements. The Ci64 portable spectrophotometer offers flexible aperture sizes and the option to add UV LED illumination to capture accurate color measurements onplastics, textiles, and papers that contain optical brightening agents.

OBAs aren't just a problem for textiles. They can also be found in paper, packaging, plastics, paints and coatings, and liquids. Read our OBA blog to learn more.

3. Metamerism

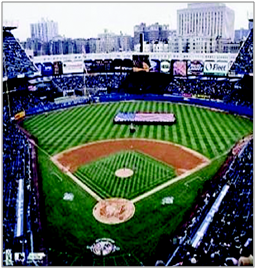

This is Yankee Stadium. How do the groundskeepers force the grass to grow in two different colors? Do they carefully spread two different types of grass seed, light and dark green?

In this case, it’s true the grass is greener on the other side. Literally. If you force it to lay in one direction, you see more of the side of the blade. Force it to lay down in another direction and you see more of the ends. This phenomenon is called gonio-appearance, or geometric metamerism.

Gonio-appearance is seen quite often in fabrics, especially piles, corduroy, and satins. If you brush the nap in one direction, you see one color. Brush it in another direction and you see a different shade. As you can imagine, textured surfaces are difficult to measure. A sphere spectrophotometer like X-Rite’s Ci7800 benchtop can measure light reflected at all angles and calculate color measurements that closely match what the human eye would see.

4. Using the Wrong Type of Spectrophotometer

To choose the right color measurement device, you need to consider the characteristics of your samples. There is no way to list all of the sample variables that can affect your measurement data, but here are a few to consider:

- Is your sample translucent or opaque? This blog explains how to choose between a transmission and a reflectance spectrophotometer.

- Is your sample wet or dry? Wet items usually appear darker, which can skew the measurement. Wet samples can also contaminate the optics to skew future measurements. This blog offers tips to measure wet samples.

- What is the temperature of your sample? Many pigments are thermochromatic, which means the samples actually change color as they become warmer. Think about how the color changes when you iron a shirt. Sometimes the hot dry section looks less chromatic until it cools down and regains some moisture. Our thermochromaticity blog explains how temperature affects color measurements.

5. Lack of Operating Procedures

Once you have identified as many variables as possible, create procedures around them. This will enable everyone involved in the color program, whether on site or off, to control color throughout a manufacturing run.

- Make a detailed list of every possible scenario.

- Create procedures that everyone must follow when measuring samples.

- Share them with everyone involved in producing color.

Otherwise your data will be ambiguous, and your color control will suffer.

Avoid Color Measurement Pitfalls

By taking these pitfalls into consideration as you develop your color measurement and management procedures, you will be more likely to achieve accurate color.

Dealing with a different pitfall? Get in touch and our Color Experts can help you troubleshoot.