To stay profitable in any industry, you must be willing and able to change and adapt to trends. Green manufacturing, with a focus on sustainability, is a growing trend that can influence your bottom line while leaving a meaningful impact on our planet.

Being sustainable means you consider your business needs as well as those of our environment and future generations. It’s a socially responsible way of doing business, and customers are considering it when making their purchasing decisions. Brands that want to stay ahead of the competition need to assure customers that they are making these changes - here's how color measurement and management solutions can help.

1. Ensure color is on target before a production run is wasted.

Color quality control shouldn’t be the last step in your production process. Measuring color throughout production is the easiest way to make sure color is on target before a production run is wasted or products are rejected, saving energy and natural resources.

Inline color measurement can enable real-time color monitoring on an extrusion production line to make precise and automatic color adjustments. Handheld spectrophotometers like the Ci6x Family can be carried around for quick spot checks. Non-contact spectrophotometers, like the MetaVue VS3200 can measure wet samples of paint, dyed fabrics, ink, or liquefied resins, so you know if color is on track without wasting electricity and time associated with drying these samples before measurement.

2. Control color at all stages of the manufacturing process.

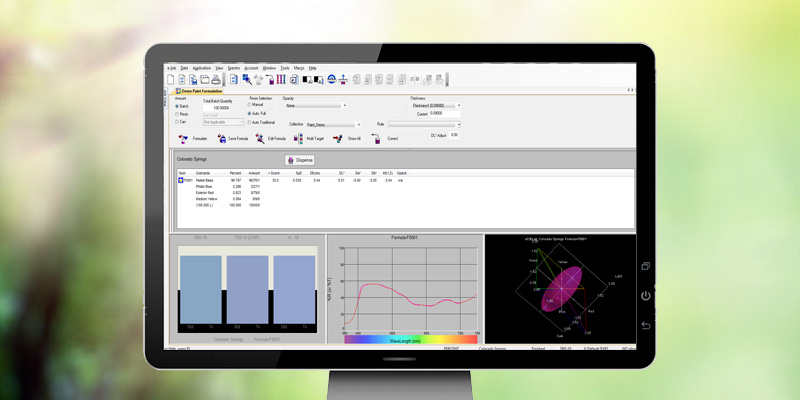

With X-Rite formulation and quality assurance software, your business can easily measure incoming materials, ensuring that color is controlled at all stages of the manufacturing process. Our software solutions also allow you to achieve target colors with recycled and natural products, meaning fewer dyes and chemicals.

Formulation software like Color iMatch can formulate recipes using leftover materials and can attempt to calculate a recipe in order to fix the color, so the whole lot is not wasted. In addition, quality assurance software like Color iQC ensures that you’re controlling color through a job-based solution, reducing inventories and waste.

3. Take the subjectivity out of color communication.

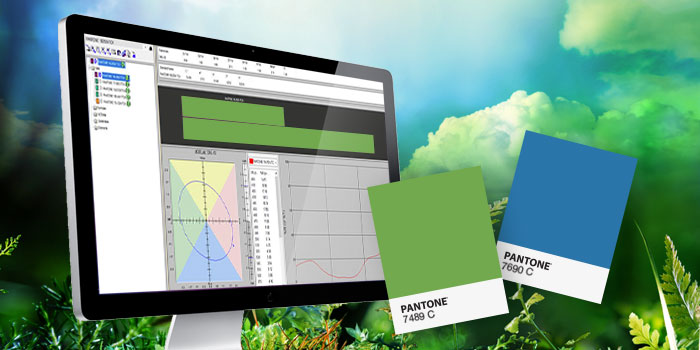

Prior to digital color communication, color accuracy was assessed by comparing physical standards with the final production output. As you can imagine, this visual assessment method resulted in time and materials. Digital solutions take the subjectivity out of color communication, as all stakeholders can look at the same spectral data and speak the same color language.

Solutions like PantoneLIVE for Plastic, Coatings, & Textile, a cloud-based database consisting of digital color standards, will save your business time and money. You’ll no longer need to ship samples back and forth from the color department to the specifier or manufacturer thanks to real-time digital color communication.

4. Examine materials virtually without producing a physical prototype.

Sending samples back and forth to get approval on color isn’t just time consuming, it can cause a lot of waste in materials, fossil fuels consumed during transport, and rework if the sample is rejected. What if you could accurately visualize your product before it’s even produced?

Our PANTORA Appearance software enables creation of highly-realistic and accurate digital materials for visualizing on 3D designs. Allowing design times to gain stakeholder buy-in without producing a physical prototype, and make changes without wasting raw materials.

What's Next?

When you move towards green manufacturing, your business becomes more competitive. Sustainability means monitoring your operation and continually looking for areas to improve. Consider your manufacturing impact on our globe and start looking for ways you can take action.

Interested in green manufacturing, but not sure where to start?

We're here to help! Fill out the form to learn more about your sustainability efforts and to identify potential areas of improvement.