繊維製品の視覚的な評価方法

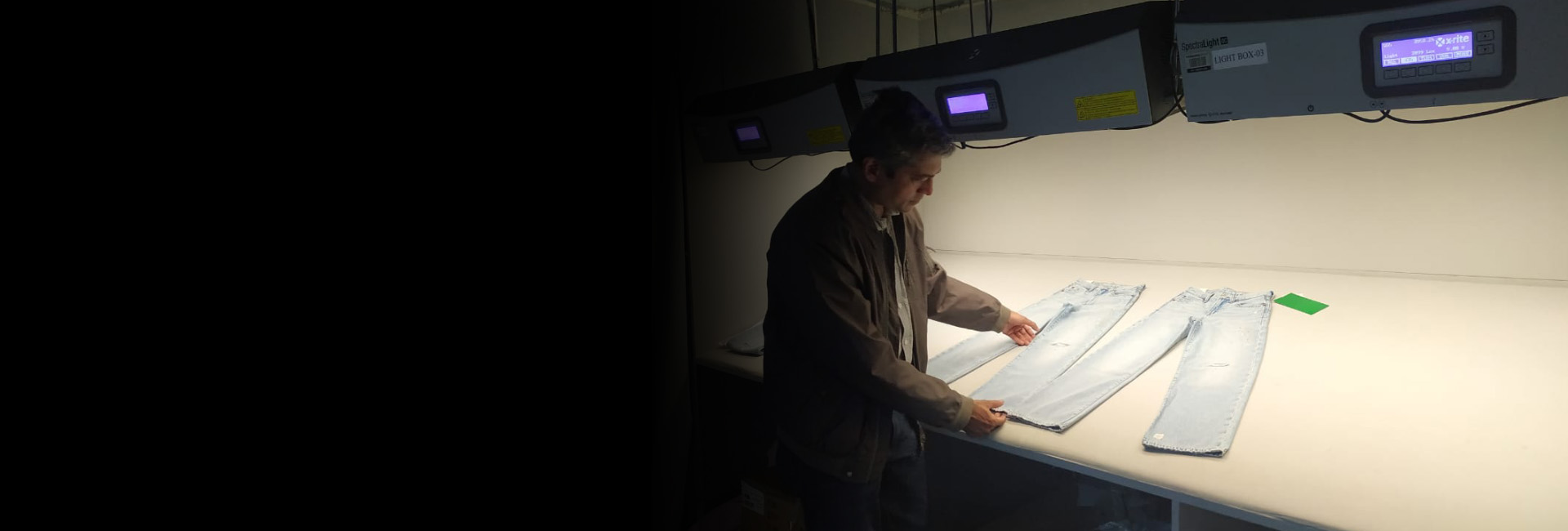

テキスタイルのカラーパレット、生地のロール、複数の衣服を並べて比較検討したり、裁断した作品を制御された照明下で評価することで、衣服の組み合わせと出荷前に色の整合性と調和を確保できます。エックスライトの照明器具は、ビューイングテーブルの上にカスタム構成で吊り下げることができ、必要な光量と視野範囲を実現できます。

課題

- 光の種類や見る角度によって色の見え方が変化することがあります。

- 異なる素材(異なる種類の生地、プラスチックボタン、金属製ジッパーなど)に塗布すると、色が変化して見えることがあります。

- 繊維に塗布された蛍光増白剤は、紫外線下で色が変化することがあります。

- 異なるサプライヤーで染色された生地は、異なる色彩プログラムに従っている場合があります。

- 大きな生地ロールや複数の生地片は、照明ブースに並べて設置できません。

- 組み合わせ時には、異なる照明条件下でもすべての部品が一致している必要があります。一致していない場合は、最終品質管理で不合格となります。

解決

SPLQCまたはJudge LEDの照明器具は、7つの光源下で色を評価するために、45度に傾斜した観察テーブルの上にチェーンで吊り下げることができます。スペクトラライトQC照明器具は、クラス最高の調光可能なフィルター付きタングステンハロゲン昼光を提供し、Judge LED照明器具は、瞬時にウォームアップし、蛍光灯技術よりもメンテナンスが少ない、環境に優しいプレミアムLED技術を提供します。照明器具は、1×2の小さな組み合わせから、必要な長さと幅まで、カスタムデイジーチェーン構成で配置でき、必要な光レベルと視野範囲を実現します。

設計、研究開発、最終品質管理の過程で、評価者は繊維製品の周囲を歩き回り、あらゆる角度から色を評価し、紫外線下での蛍光増白剤使用時を含む様々な照明条件下での色の完全性と調和性を確保することができます。照明器具を使用することで、複数の作業者が同時に評価を行うことが容易になり、目視評価における効率と連携が向上します。

結果

- より広範な市場での受容性を高めるために、消費者体験をシミュレートできます。

- 世界中のサプライヤーからの材料を評価し、色の調和を確保できます。

- 組み合わせ・出荷前に色品質の問題を特定し、時間とコストを削減できます。

- 目視評価の条件を標準化し、廃棄物を削減できます。

- サプライチェーン全体で高品質な製品を実現するための一貫した色彩プログラムを作成できます。

- 目視評価における連携を強化できます。

- ISO: 3664、3668、13076、23603、AATCC: EP9、ASTM: D1729、SAE: J361、DIN: 6173、CIE: S012/E、51.2、BSI: BS 950 Pt.2規格に準拠できます。

- 色品質を報告・追跡し、継続的な改善を図れます。

仕組み

- エックスライト社の専門スタッフと連携し、最適なサイズ、形状、電球構成を決定します。エックスライト社の照明器具は、1×2の小型の組み合わせから、アイテムの必要に応じて大型まで、様々なサイズで吊り下げることができます。

- すべてのプログラムの設定を文書化する標準操作手順を作成し、光源、照明、その他のパラメータの要件に基づいてカスタムプロファイルを作成することで、評価者間の一貫性を確保します。

- 必要に応じて、部品サプライヤーにSPLQCまたはJudge LEDライトブースの使用を依頼し、染色された生地や部品が組立出荷前に標準操作手順に基づいて視覚的に許容範囲内であることを確認します。

- 色の認識は人それぞれ異なるため、品質管理者や承認担当者の視力を検査し、色の認識方法を理解することが重要です。ファンズワース・マンセル 100 ヒューテストは、色が重要な業務に携わる社内および現場スタッフの色覚を徹底的に分析するために使用できます。

おすすめ商品

調光可能なフィルター付きタングステンハロゲン昼光 (クラス A) とオプションの LED を含む 7 つの光源を備えたこの標準光源装置は、最適な視覚評価のために利用可能な最も正確な昼光シミュレーションを提供します。

標準光源装置Judge LEDは、瞬時のウォームアップと一貫した照明を提供し、サプライ チェーン全体で正確な評価を保証する、環境に優しい LED カラー評価ツールです。

制御された照明の下で、組み合わせられた大型アイテムを視覚的に評価するためのカスタムのフィッティングおよび仕上げルームの提供が可能です。

Farnsworth-Munsell 100 Hue Test

FM 100 色相テストは、60 年以上にわたって業界で使用されてきた世界標準であり、あらゆる業界の視覚色評価者の色の判別能力を評価し、ランク付けします。

結論

SPLQCまたはJudge LEDの照明器具を吊り下げることで、サプライチェーン全体にわたる目視承認のためのチェックポイントが確保され、最終組み合わせにおける色彩の調和を確保できます。照明器具と標準光源装置を総合的なソリューションとして活用することで、人的ミスの削減、目視評価の環境標準化、そして時間とコストの削減につながります。