Spectrophotometers are color measurement devices used to specify and communicate color and monitor accuracy throughout production. There are spectrophotometers to measure just about anything, from liquids and plastics to paper, metal and fabrics. Brand owners, designers, lab techs and quality control professionals rely on them to ensure color remains consistent, from the time it’s specified until final quality check, in just about every industry.

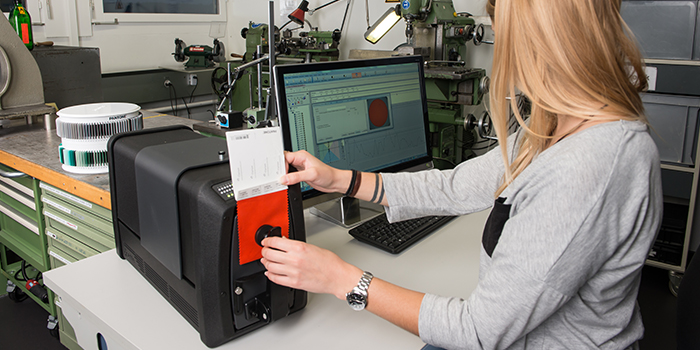

Spectrophotometers come in many shapes and sizes. There’s the practical, convenient portable spectrophotometer, small enough to fit in the palm of your hand and travel around the lab for on-site quality checks. Then there’s the larger benchtop device, standing ready to measure the most precise color for the most accurate specifications and tolerances.

Which is right for your color workflow?

Since benchtops are generally more expensive, many are left wondering if the investment is worth it. Today we’re comparing how portable and benchtop spectrophotometers perform in common color measurement scenarios so you can decide which is best for your needs.

Benchtops vs. Portables: The Big Picture

Because they’re incredibly precise and consistent, benchtops are generally the preferred choice when working with strict tolerances or developing color specifications. Color professionals who are dealing with brand colors or manufacturing components that must match at final assembly use them for color specification, formulation and quality control.

Our five most popular benchtops, from left to right: Ci7x00, Ci4200, VS450, MatchRite iVue, and Ci4100.

Our portable devices are also very accurate. They’re great for toting around the lab to spot check quality, or taking on the go to measure color for inspiration and design.

View our family of benchtop spectrophotometers

View our family of portable spectrophotometers

How will you use your spectrophotometer?

1 – To measure transmission.

If you’re measuring liquids like orange juice, laundry detergent or shampoo, benchtops offer something you can’t get in a portable device – transmission measurements. This calculates through the object being measured. They can also measure both translucence and haze for plastics and packaging, such as 2-liter bottles and clear blister packs, to ensure the correct amount of opacity.

2 – To formulate colorants.

Benchtops are a top choice for color formulation. They’re also widely used for formulating varying levels of opacity in plastics, and when paired with Color iMatch software, to formulate liquid dyes for textiles and colorants for paints.

Color iMatch enables fast, accurate color analysis and colorant formulation for a variety of applications.

3 – To create standards.

Creating standards is a very important step in a color program. If you specify the wrong color, how can you expect to achieve accuracy during production?

When the highest level of accuracy is needed, benchtops are usually the go-to instrument for creating standards, because their repeatability and reproducibility is so good.

4 – As part of a group of instruments.

If you’re working across multiple sites, or even just using different instruments in your lab, you need to consider each instrument’s repeatability. When there are variances in measurements using the same instrument, you can expect even more variability when you’re dealing with multiple instruments.

By design, benchtops have the highest level of repeatability, resulting in tighter correlation among instruments. While our portables are also excellent, on the high end, you can expect a 0.13 variance for a portable, and a 0.06 for our leading Ci7860 benchtop. Although that doesn’t sound like a whole lot, when you start multiplying that tolerance difference against the number of instruments you’re using, it can eat up quite a bit of your tolerance.

5 – To carry around the lab.

No comparison here… portables are the best choice for toting around the lab. They’re very useful for production spot checks to ensure color is consistent throughout the run. They can also be used in the field to capture color information for use in designs or for quality checks at supplier sites. Many offer Bluetooth connectivity for immediate color analysis, while others can be plugged into the master computer to download data.

6 – For quality control.

While many people think of portable spectrophotometers for quality control because they’re portable, there are a few other things you need to consider.

First – illumination spot size. In a perfect world, our measurements of a 6 mm spot and 25 mm spot would be identical. However, if your sample has a small defect, say a tiny scratch, lint, dirt, or dust, that defect will take up a large portion of the small measurement area and return incorrect measurement data. Differences in texture and directionality as well as imperfections in the sample can also skew your results. Benchtops tend to have a larger measurement area and do a better job of averaging out imperfections.

Second – backing. Unless your sample is completely opaque, whatever is behind it can show through when you take a measurement and change the results. Benchtops come with a built in backer, so you don’t have to think about it. When using a portable, the portability is great, but you need to also use a backer for consistent results.

Third – video preview. Our benchtops have this fantastic feature to help you get to better measurements, and videos can be saved as proof of the exact area you measured.

For continuous monitoring of your manufacturing process, we offer inline solutions for quality control. Learn more by reading our inline solutions blog.

7 – To measure optical brighteners.

One final consideration – if you’re dealing with optical brighteners, you need an instrument that is UV calibrated to maintain consistency. While common on benchtop units, some portables, like the Ci64UV, can also perform UV calibration.

All of our UV units come calibrated to D65, but can be calibrated to other light sources as required. They also include a plastic UV calibration plaque for paper, plastics, and textiles, and we offer additional standards for both textile and paper applications.

So, which did you choose?

We know it’s not that easy. It all comes down to what you’re measuring and how tight your tolerances are. Your next step is to review the specs for each device and make a decision based on the considerations we have offered in this post.

Or get in touch with our color experts. They know our devices inside and out and are happy to guide you toward the right choice.