Il s’agit du troisième article de notre série MeasureColor en action, qui présente les principales fonctionnalités vous aidant à bénéficier d’une production d’impression plus intelligente et plus efficace.

MeasureColor : optimisez l’engraissement pour une meilleure qualité d’impression

Pour garantir une qualité d’impression régulière, il est essentiel de contrôler l’engraissement, une variable cruciale mais souvent négligée. L’engraissement joue un rôle majeur dans la précision des couleurs, la netteté de l’image et l’impact visuel global, en particulier dans les flux de production d’emballages et à gamut étendu.

Avec MeasureColor, les imprimeurs ont accès à des outils avancés qui facilitent le suivi, la gestion et l’amélioration de l’engraissement en temps réel, sans approximations.

Comprendre l’engraissement : une mesure essentielle du contrôle de la couleur

Dans les procédés CMJN et à gamut étendu comme CMJNOVV, l’engraissement est un indicateur crucial de la qualité de l’impression. Lorsque l’encre s’étale sur le support, les points imprimés deviennent plus grands que prévu, ce qui altère l’équilibre des couleurs et la clarté de l’image. S’ils ne sont pas correctement gérés, même de petites variations dans l’engraissement peuvent entraîner des incohérences visibles.

- Suivi des valeurs d’engraissement sur l’ensemble du gamut

- Comparaison des courbes d’engraissement mesurées avec vos profils de référence

- Validation de l’impression des aplats dans les limites de la tolérance

Cela permet une analyse globale des familles de couleurs ainsi qu’une évaluation granulaire des teintes individuelles, offrant aux conducteurs les informations dont ils ont besoin pour effectuer des ajustements précis.

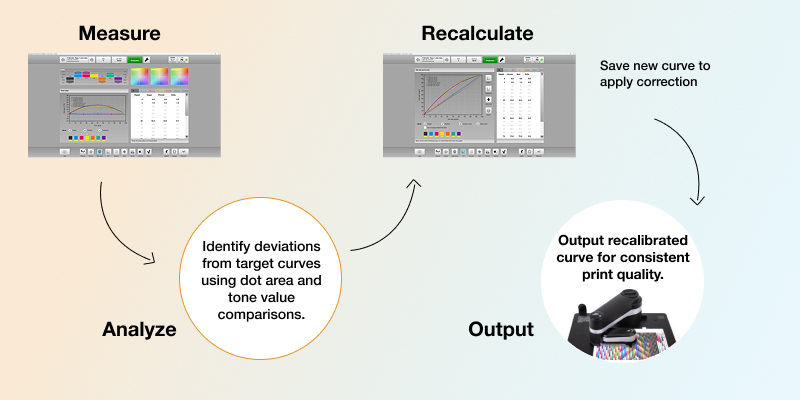

Optimisation facile de la courbe CTP

Les méthodes traditionnelles de correction de l’engraissement nécessitent des formes d’essai linéaires et des tirages de presse multiples. MeasureColor élimine cette source d’inefficacité en permettant le recalcul de la courbe CTP directement dans le logiciel.

Voici comment :

- Importez ou créez vos courbes initiales

- Mesurez les résultats imprimés

- Recalculez les courbes optimisées sur la base du comportement réel de l’engraissement

- Exportez des courbes de compensation mises à jour compatibles avec la plupart des systèmes RIP

Cette itération courbe sur courbe réduit le temps de configuration, le gaspillage de matériaux et le risque d’erreurs manuelles, ce qui aide les équipes de presse à boucler la boucle plus rapidement.

La garantie d’une qualité d’impression basée sur les données

MeasureColor donne aux imprimeurs un avantage concurrentiel en transformant les ajustements manuels et fastidieux en décisions basées sur des données. L’optimisation de l’engraissement vous assure :

- Une meilleure fidélité des couleurs

- Une réduction du gaspillage d’encre

- Des délais d’exécution des travaux accélérés

- Une satisfaction accrue des clients

Qu’il s’agisse de presses flexo, offset, hélio ou numériques, MeasureColor fournit les informations et les outils nécessaires pour obtenir des résultats réguliers pour chaque travail.

Vous avez manqué la série d’articles MeasureColor en action ?

Prochains articles de la série

Cet article fait partie de notre série d’articles MeasureColor en action. Ne manquez pas le dernier article :

- Nº 4 : MeasureColor : maximisez l’opacité de l’encre blanche

Découvrez comment une variation de 3 % de l’opacité de l’encre blanche peut réduire la consommation d’encre de 33 % et comment MeasureColor facilite l’optimisation de la qualité et des coûts à chaque tirage.

Rattrapez les sujets précédents :

- Nº 1 : MeasureColor : une interface conviviale pour des décisions d’impression plus rapides

Découvrez comment ChromaTrack élimine les tâtonnements en aidant les conducteurs à atteindre plus rapidement la bonne couleur grâce à des corrections guidées et prédictives. - Nº 2 : MeasureColor : la gestion des couleurs cibles numériques en toute fiabilité

Découvrez comment le Reference Manager simplifie l’organisation et l’application des couleurs cibles numériques et des profils ICC pour obtenir des résultats réguliers tout au long des flux de production.

Vous souhaitez savoir comment MeasureColor peut vous aider à optimiser l’engraissement pour améliorer la qualité d’impression et réduire les coûts ? Contactez nos experts couleur.