Il s’agit du deuxième article de notre série MeasureColor en action, qui présente les principales fonctionnalités vous aidant à bénéficier d’une production d’impression plus intelligente et plus efficace.

MeasureColor : la gestion des couleurs cibles numériques en toute fiabilité

Dans les environnements d’impression complexes et rapides d’aujourd’hui, la gestion efficace des couleurs cibles numériques et des profils ICC est essentielle pour fournir des résultats réguliers et de haute qualité. Sans système structuré, il est facile de perdre le contrôle de vos bibliothèques de couleurs, ce qui entraîne des erreurs d’impression, du gaspillage et des temps de configuration plus longs.

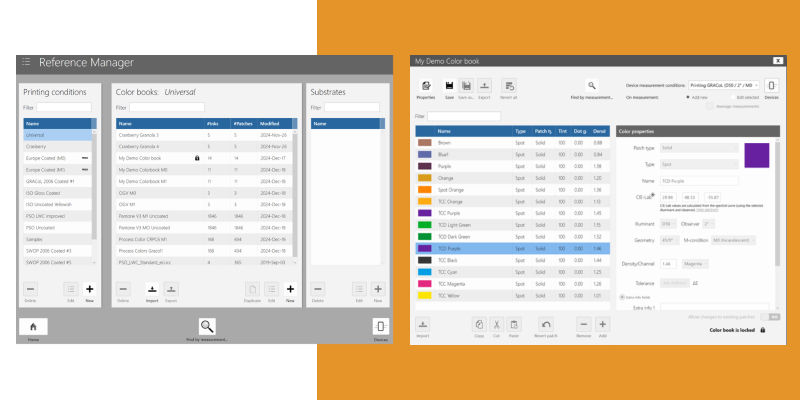

C’est là que le Reference Manager de MeasureColor intervient. Il fournit une solution centralisée et intelligente pour aider les imprimeurs à organiser, maintenir et déployer des standards de couleur numériques en toute fiabilité.

Un système plus intelligent pour la gestion des couleurs

Le Reference Manager de MeasureColor vous offre une méthode plus intelligente pour gérer vos couleurs cibles numériques. Il organise vos données colorimétriques en nuanciers, regroupés par condition d’impression, une combinaison de variables telles que la technique d’impression, le type d’encre, le support et les conditions de mesure (condition M).

- Stocker des couleurs cibles génériques utilisables dans toutes les conditions

- Assigner des cibles spécifiques sous les configurations d’impression pertinentes

- Organiser les standards en couleurs master et dépendantes

Intégration facile avec votre flux de production

Que vous exploitiez des flux de production offset, flexo, hélio ou numériques classiques, MeasureColor garantit l’alignement de vos couleurs cibles entre les différents services et sites d’impression.

- Importation/exportation directe de formats de fichiers standardisés

- Accès instantané aux cibles depuis les outils d’AQ ou de salle d’impression

- Intégration avec le logiciel InkFormulation basé sur CxF

- Accès aux bibliothèques de standards PantoneLIVE pour une reproduction régulière des couleurs de marque sur tous les supports et à travers tous les procédés d’impression

En garantissant que tous les conducteurs travaillent à partir d’une référence unique et fiable, vous réduisez les variations et obtenez une correspondance des couleurs plus rapide et plus régulière d’un travail à l’autre.

Pourquoi c’est important : la qualité d’impression commence avec la bonne cible

Une mauvaise gestion des bibliothèques de couleurs entraîne souvent une confusion et un gaspillage de matériaux.

- Les conducteurs utilisent toujours la version correcte des couleurs cibles

- Les profils ICC sont à jour et faciles à appliquer

- Les variations des tons directs sont suivies et réduites au minimum

- Les décisions en matière de couleurs sont basées sur une comparaison spectrale plutôt que visuelle

MeasureColor ne se contente pas de stocker vos couleurs cibles, il apporte intelligence et visibilité à l’ensemble de votre processus d’impression.

Avec MeasureColor, vous vous connectez directement aux couleurs cibles de votre base de données. Grâce à une intégration parfaite, MeasureColor garantit que vos couleurs cibles restent toujours conformes aux standards du secteur. Que vous importiez des fichiers CxF, MIF, CSV ou CGATS.17, ou que vous travailliez avec des profils ICC pour des gammes de couleurs étendues, MeasureColor vous offre la flexibilité et le contrôle dont vous avez besoin.

Prochains articles de la série

Cet article fait partie de notre série d’articles MeasureColor en action. Ne manquez pas le programme complet :

- Nº 3 : MeasureColor : optimisez l’engraissement pour une meilleure qualité d’impression

Découvrez comment le suivi de l’engraissement en temps réel et l’optimisation de la courbe CTP aident les conducteurs de presse à améliorer la précision des couleurs, à réduire le gaspillage et à maintenir la régularité. - Nº 4 : MeasureColor : maximisez l’opacité de l’encre blanche

Découvrez comment une variation de 3 % de l’opacité de l’encre blanche peut réduire la consommation d’encre de 33 % et comment MeasureColor facilite l’optimisation de la qualité et des coûts à chaque tirage.

- Nº 1 : MeasureColor : une interface conviviale pour des décisions d’impression plus rapides

Découvrez comment ChromaTrack élimine les tâtonnements en aidant les conducteurs à atteindre plus rapidement la bonne couleur grâce à des corrections guidées et prédictives.

Vous souhaitez savoir comment MeasureColor peut vous aider à gérer vos couleurs cibles numériques et à améliorer votre qualité d’impression ? Contactez nos experts couleur.