Looking forward to the X Games? Kicking off next week in Aspen, the annual sporting competition draws thrill seekers from around the world to participate in Xtreme events, such as skiing, snowboarding, and snowmobiling.

Of course, this living-on-the-edge lifestyle isn’t for everyone. Luckily, with X-Rite you don’t have to be a daredevil to enjoy Xtreme color! Here’s a list of our most innovative solutions to help you achieve the greatest possible results… from the safety of your office, shop, or lab.

Total Appearance Capture™

Our TAC Ecosystem brings the excitement of 3D into the design and approval process, so what you see on screen is what you see in the final product. Simply scan in your physical materials, then see how they will look with the exact same optical characteristics as the real material when rendered in a virtual scene. You can even visualize the impact of changing gloss levels or special-effect pigment concentrations.

Check out our free, on-demand webinar to see how TAC can help you take design virtualization to an Xtreme level!

eXact™ Xp

Its no secret brands are going to Xtreme lengths to catch your eye on store shelves. Flexible film is a popular solution, but even the most sophisticated converters can find it difficult to color control. The eXact Xp handheld spectrophotometer faces the challenge head on with special enhancements to accurately and consistently measure on a variety of film substrates, including lamination materials and base structures.

Its no secret brands are going to Xtreme lengths to catch your eye on store shelves. Flexible film is a popular solution, but even the most sophisticated converters can find it difficult to color control. The eXact Xp handheld spectrophotometer faces the challenge head on with special enhancements to accurately and consistently measure on a variety of film substrates, including lamination materials and base structures.

The costs of getting color wrong on packaging can be significant. With the eXact Xp, you can get it right, the first time. Read more about the eXact on our blog or visit our site to learn how it is revolutionizing the way printers and converters manage color.

Inline Measurement Systems

Imagine being able to keep an eye on production color without leaving your desk. X-Rite’s inline color measurement solutions use a mounted spectrophotometer to monitor manufactured color as it’s moving down the production line. Depending on the application, the spectro may be fixed or mounted on a moving frame or robotic arm to cover a larger area. If color starts to move even a tiny bit out of spec, the system will alert operators to make corrections before product is wasted. Some systems can even make real time closed-loop color corrections without operator intervention!

The TeleFlash445 spectrophotometer mounted on a traversing beam is automatically measuring the left, middle and right side of this sheet during production.

Check out our blog to learn how industries such as paper, textiles, plastics, glass and automotive are taking advantage of X-Rite’s inline measurement solutions for Xtremely efficient color results.

PantoneLIVE

Brand colors are a crucial part of every company’s identity. But with various substrates, different print technologies, and production occurring around the globe, achieving consistent brand color is no easy feat. PantoneLIVE is focused on protecting brand colors to ensure consistent color across everything from flexible materials to corrugated board. When a brand’s digital color palette lives in the PantoneLIVE cloud, it can be accessed by any authorized user from anywhere in the world, from brand owner and designer to prepress and pressroom; plus colors can be measured at every stage and compared to up-to-date digital standards for an Xtreme level of control.

Brand colors are a crucial part of every company’s identity. But with various substrates, different print technologies, and production occurring around the globe, achieving consistent brand color is no easy feat. PantoneLIVE is focused on protecting brand colors to ensure consistent color across everything from flexible materials to corrugated board. When a brand’s digital color palette lives in the PantoneLIVE cloud, it can be accessed by any authorized user from anywhere in the world, from brand owner and designer to prepress and pressroom; plus colors can be measured at every stage and compared to up-to-date digital standards for an Xtreme level of control.

Read more about how PantoneLIVE can remove ambiguity and reduce human error and waste in your packaging workflow!

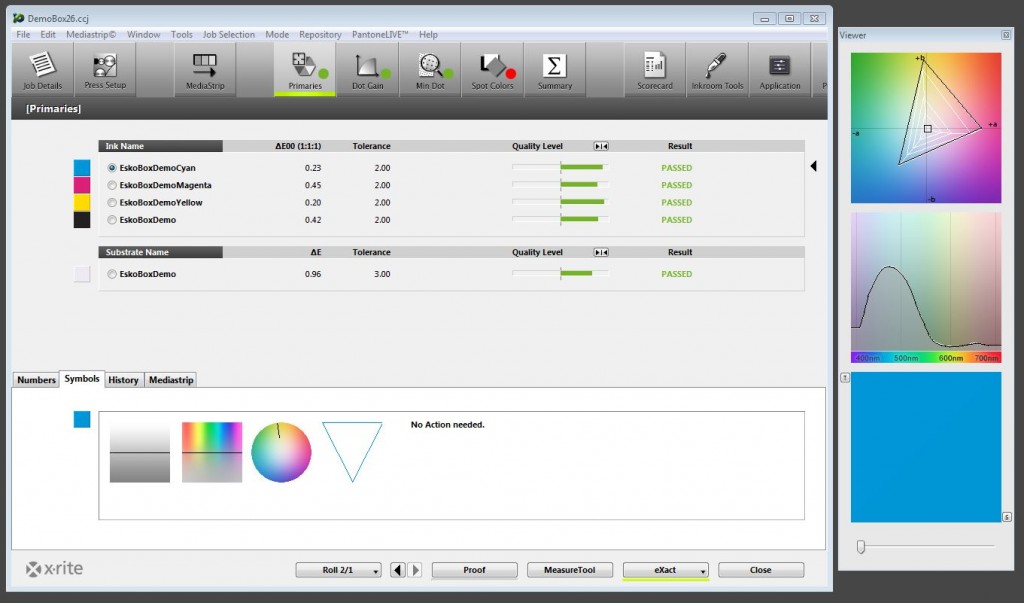

ColorCert

If you find meeting customer specifications to be Xtremely challenging, ColorCert may be the answer. It’s a customizable and intelligent statistical process control software suite that helps print providers take charge of their entire production platform. Using real-time data, managers can easily understand color tolerances and verify whether production is meeting expectations. Unlike other solutions, ColorCert has the ability to measure not just solid colors, but tints, overprints, gray balance, undertones, and custom built colors, then tolerance each in a meaningful way. And brand owners can use it as well to manage a global supply chain.

If you find meeting customer specifications to be Xtremely challenging, ColorCert may be the answer. It’s a customizable and intelligent statistical process control software suite that helps print providers take charge of their entire production platform. Using real-time data, managers can easily understand color tolerances and verify whether production is meeting expectations. Unlike other solutions, ColorCert has the ability to measure not just solid colors, but tints, overprints, gray balance, undertones, and custom built colors, then tolerance each in a meaningful way. And brand owners can use it as well to manage a global supply chain.

ColorCert is already helping printers and packaging converters of all sizes achieve Xtreme color. Is it right for you? Learn more.

Color Formulation Software

Whether you work in paints, plastics, textiles, or printing, fast, accurate color is the key to producing trending colors while they’re still trending. Instead of the dozen iterations usually required to formulate a color by eye, formulation software can get you in tolerance on the first try or with one or two corrections, saving an Xtreme amount of time and money! Plus, since it calculates recipes from the colorants and dyes you have on hand, you’ll experience a lot less waste.

Our formulation solutions easily fit into every industry and any workflow, and ROI is Xtremely fast. Check out our blog to learn more about what we have to offer.

Ready for Xtreme Color?

While the X games are fun to watch, we find Xtreme color to be a much more rewarding endeavor for color enthusiasts of all stripes! Get in touch to learn how you can make it a reality.