The spectral reflectance curve provided by a spectrophotometer is commonly known as the color’s “fingerprint”.

Spectrophotometers are color measurement devices used to capture and evaluate color. As part of a color control program, brand owners and designers use them to specify and communicate color, and manufacturers use them to monitor color accuracy throughout production. Spectrophotometers can measure just about anything, including liquids, plastics, paper, metal and fabrics, and help ensure that color remains consistent from conception to delivery.

Today we’ll look at how spectrophotometers work, how they are used, and the most common types available today.

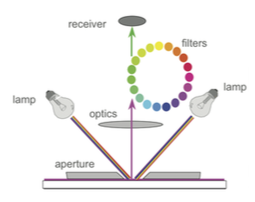

How spectrophotometers work

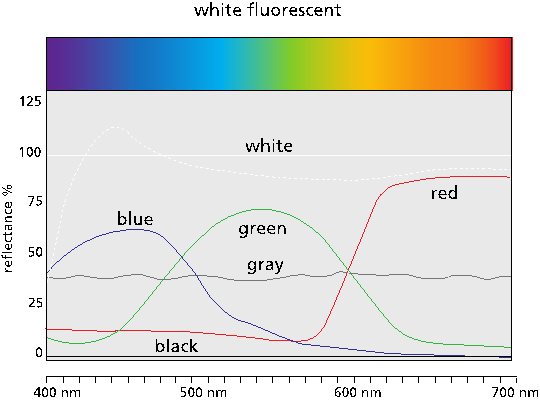

Spectrophotometers measure reflected or transmitted light across the spectrum and create a visual curve that describes the color on that substrate, under that lighting condition.

A white surface reflects all light energy across the visible spectrum, so its reflectance curve is a straight line at approximately 90 to 100% reflectance. Black absorbs almost all light energy, so its reflectance curve is flat and approaches 0% reflectance. A mid-range gray, made by combining equal portions of white and black, is represented by a straight line at 50% reflectance. Other colors spike near the part of the spectrum that is most reflected.

Types of spectrophotometers

There are three primary types of spectrophotometer, and selection depends on the application and desired functionality.

-

0º/45º (or 45º/0º): The most common spectrophotometer, this instrument measures light reflected at a fixed angle to the sample, usually 45˚, and can exclude gloss to most closely replicate how the human eye sees color. They are commonly used for measuring color on smooth or matte surfaces.

- Spherical: Spherical instruments can measure light reflected at all angles to calculate color measurements that closely match what a human eye would see. They are commonly used for measuring color that has been applied to textured surfaces such as textiles, carpets and plastics, as well as shiny or mirror-like surfaces, including metallic inks, printing over foil, and other highly glossy surfaces.

- Multi-Angle: A multi-angle instrument views the color of a sample as if it is being moved back and forth, just as you would twist a sample to see the color at various angles. Today’s multi-angle instruments are used for specially coated pigments and special effect colors with additives such as mica and pearlescents, such as nail polish and automotive coatings.

Spectrophotometers come in a range of sizes, from small, portable devices to large benchtop instruments.

Common applications

Spectrophotometers are used in every industry that requires accurate color. From cardboard packaging to laundry soap to carpeting and small plastic parts, these devices help ensure that the color being produced matches the color that was originally specified.

There are many software packages available to help manufacturers track and control color as it moves through production, and to ensure that spectrophotometers are working within specification.

Maintenance

Spectrophotometers must be re-calibrated often to bring them back to known standards. It’s also necessary to periodically send them in for routine service to account for inevitable variability. As long as they are properly maintained and used correctly, spectrophotometers will continue to provide accurate color data, time after time.

Watch to Learn More