Fünf wichtige Komponenten eines Programms zur Qualitätskontrolle und sicherung

Schritt 1: Quantifizierung von Farben mit einem Spektralfotometer

Das menschliche Sehvermögen ist subjektiv. Ausdrücke wie „ein bisschen heller“ oder „etwas dunkler“ sind auslegungsfähig. Deshalb sind Spektralfotometer unverzichtbar. Diese Geräte messen Farben, indem sie analysieren, wie Licht durch eine Oberfläche dringt oder von ihr reflektiert wird, und eine spektrale Reflexionskurve erstellen – im Wesentlichen den einzigartigen Fingerabdruck einer Farbe. Dieser datengestützte Ansatz sorgt für objektive Entscheidungen und für konstante, wiederholgenaue Ergebnisse.

Schritt 2: Festlegung realistischer Farbtoleranzen

Farbtoleranzen legen fest, wie groß die zulässige Abweichung zwischen Ihrer Soll- und Ist-Farbe ist. Bei zu enger Toleranz verbringen Sie viel Zeit mit der Suche nach Perfektion. Eine zu lockere Toleranz birgt das Risiko von Kundenunzufriedenheit. Daher kommt es auf die richtige Balance an.

Die Toleranzberechnung ist ein schwieriges Thema. Laden Sie unser kostenloses Whitepaper herunter, oder sehen Sie sich unser Demand-Webinar an, um zu erfahren, wie Sie das richtige Farbmodell auswählen (die gängigsten Farbmodelle sind L*a*b* und L*C*h°), das richtige Toleranzmodell wählen und Ihre Toleranzen umsetzen.

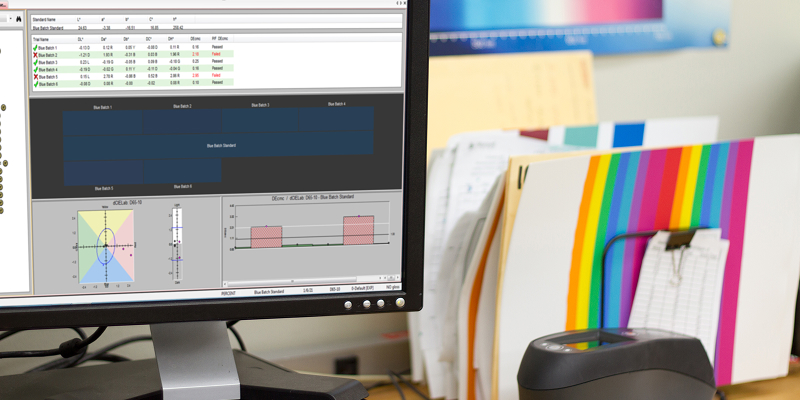

Schritt 3: Verwendung von QC-Software zur Analyse und Verfolgung von Farben

Software zur Qualitätskontrolle und sicherung wie Color iQC von X-Rite hilft Ihnen, Produktionsproben mit Standards zu vergleichen, Ergebnisse außerhalb der Toleranzen zu erkennen und Trends im Zeitverlauf zu verfolgen. Sie ist besonders nützlich für globale Teams, weil sie dafür sorgt, dass alle an einem Strang ziehen und verantwortlich sind.

Schritt 4: Visuelle Beurteilung

Obwohl Geräte wichtig sind, spielt die visuelle Beurteilung immer noch eine Rolle – vor allem bei weniger kritischen Anwendungen. Allerdings ist sie nicht narrensicher. Lichtverhältnisse, Schulung und sogar Farbsehschwächen können sich auf die Ergebnisse auswirken.

Tatsächlich haben jeder 13. Mann und jede 300. Frau eine bestimmte Farbsehschwäche. Alle, die an der visuellen Beurteilung beteiligt sind, sollten den FM 100 Hue-Test machen – und bestehen. Denn Personen, die für die Qualitätskontrolle und sicherung zuständig sind und ein unterdurchschnittliches Farbsehvermögen haben, treffen schlechte Entscheidungen. Um Ihr Farbsehvermögen ausfindig zu machen, sollten Sie unseren Online-Farbsehtest machen und ihn mit Ihren Freunden und Kollegen teilen! (Er macht Spaß, ist aber kein Ersatz für den echten FM 100 Hue Test.)

Schritt 5: Farbbeurteilung unter standardisierten Lichtbedingungen

Die Betrachtung einer Probe auf dem Parkplatz gilt nicht als D65-Standardbeleuchtung. Natürliches Tageslicht ist dynamisch. Damit es mit der Standardbeleuchtung übereinstimmt, können Sie die Beurteilung nur zwischen 11 und 14 Uhr bei Tageslicht am nordischen Himmel vornehmen. Was ist, wenn es ein bewölkter Tag ist? Und was macht die dritte Schicht?

Natürliches Tageslicht schwankt. Eine kalibrierte Lichtkabine wie die Judge LED oder SpectraLight QC simuliert Standard-Lichtverhältnisse (wie D65), sodass Sie unabhängig von Uhrzeit und Wetter zuverlässige Farbentscheidungen treffen können.

Möchten Sie Ihre Farbqualitätskontrolle verbessern?

Wenn Sie immer noch mit Reklamationen oder Abweichungen zu kämpfen haben, ist es vielleicht an der Zeit, Ihren Prozess zu optimieren. Angefangen von E-Learning-Kursen bis zu Schulungen vor Ort bietet X-Rite die Tools und das Fachwissen, um Ihnen beim Aufbau eines zuverlässigen, ROI-gestützten Farbprogramms zu helfen.

Die Investitionen in die notwendigen Tools für ein Qualitätskontrollprogramm mögen zwar abschreckend wirken. Doch nicht zu investieren, wird Sie auf lange Sicht mehr kosten. Wir können sogar Ihren aktuellen Farbworkflow evaluieren und Vorschläge machen, wie sich Ihre Investition schnell amortisiert.

Nehmen Sie Kontakt zu unseren Farbexperten auf, um mehr zu erfahren.