Jedną z wielu korzyści płynących z bliskiej współpracy z naszymi klientami jest możliwość pomocy we wdrażaniu unikalnych procesów związanych z pomiarem barwy. Dzięki opisom konkretnych przypadków firm dowiesz w jaki sposób inni zarządzają barwą i jaki to ma wpływ na ich sukces finansowy. Niezależnie od tego, czy szukasz porady, czy nowego sposobu zarządzania barwą przejrzyj nasze studia przypadków, aby zobaczyć, czego możesz się nauczyć od firm takich jak Twoja.

Producent pojazdów elektrycznych zmniejsza zużycie gipsu, pianki i drewna o 2,5 tony dzięki rozwiązaniom do obsługi materiałów cyfrowych firmy X-Rite

Dowiedz się, w jaki sposób producent pojazdów elektrycznych stał się pionierem w zakresie zrównoważonego rozwoju dzięki materiałom cyfrowym opartym na rozwiązaniach X-Rite Appearance.

Ultimate Textile Case Study

Ultimate Textile was looking for the next generation in handheld devices to ensure the continued delivery of the highest quality dyed fabrics to its customers.

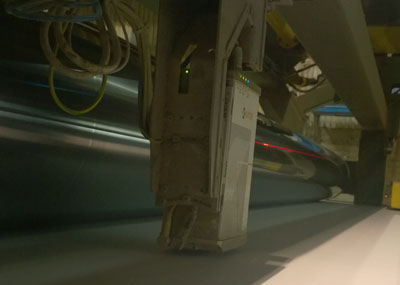

Manufacture d’Histoires des Deux-Ponts

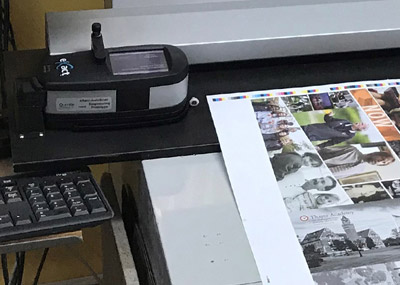

French printer Manufacture d’Histoires des Deux-Ponts adopts closed-loop color control to optimize its offset press.

T&N Printing Takes All the Guesswork Out of Color

Read this case study to learn how T&N Printing, a reputable offset printer, has reduced make-ready by 66% by presetting ink keys using IntelliTrax and Rutherford closed-loop system

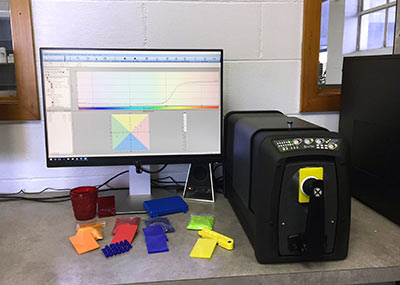

Rozwiązania X-Rite pomagają Teknor w poprawie wizualnej oceny barw

Dowiedz się, dlaczego firma Teknor wybrała narzędzia do oceny wizualnej X-Rite, zarówno w swoim laboratorium, jak i w dziale kontroli jakości, oraz w jaki sposób rozwiązania X-Rite pomogły im zaimponować klientom.

X-Rite Pantone pomaga Perfetti Van Melle uzyskać wysokiej jakości barwy i poprawić odchylenia barw

Firma Perfetti Van Melle zwróciła się do X-Rite o pomoc w opracowaniu programu jakości druku cyfrowego, aby osiągnąć spójność barw produktów marki na półkach sklepowych na całym świecie.

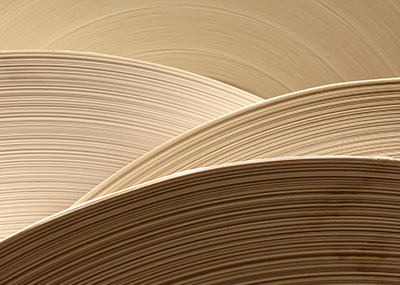

Austriacka papiernia skraca czas transmisji o 50%

Dowiedz się, w jaki sposób zamknięty układ kontroli barw firmy X-Rite pomógł wiodącej papierni utrzymać barwę w granicach specyfikacji, a także zarządzać surowcami pochodzącymi z recyklingu, złożonymi wymogami i inicjatywami na rzecz zrównoważonego rozwoju.

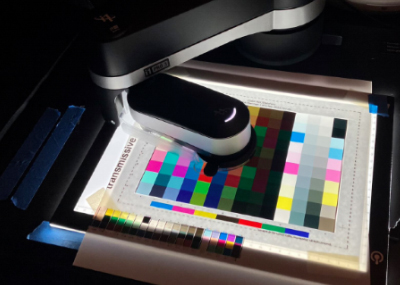

I1Pro 3 Plus i i1iO umożliwiają systemowi Primary Color rozszerzenie możliwości zarządzania barwami na materiały z siatki (mash), perforowane i podświetlane (backlit)

Primary Color produkuje materiały drukowane od 1984 roku. Dowiedz się, w jaki sposób i1Pro 3 Plus i i1iO umożliwiają im osiągnięcie wysokiej jakości obrazu na podświetlanym materiale przy mniejszej ręcznej korekcji i retuszu.

Soap & Glory Uses X-Rite Digital Solutions for Color Success

Read how X-Rite's digital color solutions enabled No7 Beauty Company to set clear color expectations for Soap & Glory packaging across the supply chain.

PantoneLIVE i ColorCert wspierają firmę Dongguan Modern Paper w usprawnieniu produkcji i szybszym dopasowaniu barw

Z naciskiem na zrównoważony rozwój, Dongguan Modern Paper znalazło sposób na szybkie uzyskanie dokładnie odwzorowanej barwy w celu zoptymalizowania produkcji i minimalizacji odpadów w swoich zakładach produkcyjnych oraz dla klientów.

Firma Siegwerk przyspiesza opracowywanie farb nawet o 50% dzięki oprogramowaniu Autura Ink

Pobierz to bezpłatne studium przypadku, aby dowiedzieć się, jak firma Siegwerk przyspieszyła opracowywanie farb dzięki Autura Ink, zintegrowanej platformie do opracowywania i kontroli jakości farb dla producentów i dostawców farb.

Austis Increases Productivity with X-Rite Solutions

Read the story of how Austis a leading manufacturer of water based paints and construction products reduced their color preparation time from one color every two weeks to preparing five or six paint colors per day.

X-Rite ColorCert poprawia barwę opakowań i dostarcza spójne wyniki jakościowe

Dowiedz się, jak ColorCert pomógł firmie Asda i jej preferowanym drukarniom oszczędzić czas i koszty oraz uspójnić barwy produktów na półce sklepowej.

Rewolucja w ocenie barwy: modernizacja komory świetlnej Judge LED w firmie Sympatex

Niniejsze studium przypadku przedstawia udane wdrożenie przez firmę Sympatex komory świetlnej Judge LED, zwiększającej precyzję wizualnej oceny barwy, przy jednoczesnym wzmocnieniu zrównoważonego rozwoju.

Firma Gul Ahmed Textile Mills Limited zapewnia skandynawskiej marce wyposażenia wnętrz dokładne barwy bez konieczności wysyłania fizycznych próbek

Dowiedz się, jak firma Gul Ahmed wykorzystuje kompleksowy pakiet cyfrowych bibliotek barw X-Rite Pantone, aby przystąpić bezpośrednio do produkcji po przesłaniu pierwszej próbki laboratoryjnej i skrócić proces zatwierdzania próbek o 75%.

.jpg?la=pl-PL&h=285&w=400&hash=4C7D3611A0CDD7188EB5A3D5465FFF25)

Poprawa materiałów cyfrowych w projektach motoryzacyjnych u wiodącego producenta samochodów luksusowych

Dowiedz się, jak ten producent samochodów luksusowych tworzy materiały cyfrowe do dopasowywania barw w branży motoryzacyjnej przy użyciu oprogramowania PANTORA i spektrofotometru MA-T12, aby usprawnić czynności związane z projektowaniem i wizualizacją 3D.

Stayton Ace Hardware Drives Customer Satisfaction with MetaVue™

Learn how MetaVue has helped the paint counter at the Stayton Ace Hardware store make their customer desires a reality, resulting in increased paint revenue and reduced costs due to mistints.

Quality Guaranteed Through Inline Measurement

Smurfit Kappa the market leader in the sustainable development and production of packaging solutions from corrugated cardboard, solid board and carton board, both from fresh fibres and from recycled waste paper.

Plastic Resins Case Study

X-Rite solutions were a critical element that enabled Plastic Resins to efficiently start up operations.

Nail Polish Color As You Imagined It!

Inkk offers a unique service that allows creation of custom nail polish colors to match a color found in a dress, a car or any other inspirational item based on a submitted image.

MetaVue: An Investment with Fast ROI for California Paints

California Paints dramatically improves the process to color perfection with MetaVue, one of the best color measurement instruments they’ve ever seen.

X-Rite Provides a Leading Packaging Manufacturer with an Integrated Color Workflow for Streamlined Success

Learn how a leading packaging manufacturer transformed color evaluation from a subjective visual process into an integrated and connected color workflow for improved color accuracy.

Home Hardware Reimagined Paint Color Matching with MetaVue™

Learn how a Home Hardware store used MetaVue to measure the most difficult paint matching samples with 50% more accuracy and ease of use than other models.

X-Rite eXact Auto-Scan Helps J&R Graphics Work “Faster, Better, Cheaper, Period.”

J&R Graphic added the eXact Auto-Scan to their workflow and cut their make ready in half!