With so many requests for innovative bases, transparency, and special effects, formulating color for paint, coating, and plastic applications can be a challenge. To keep up, formulation software needs to be innovative, too.

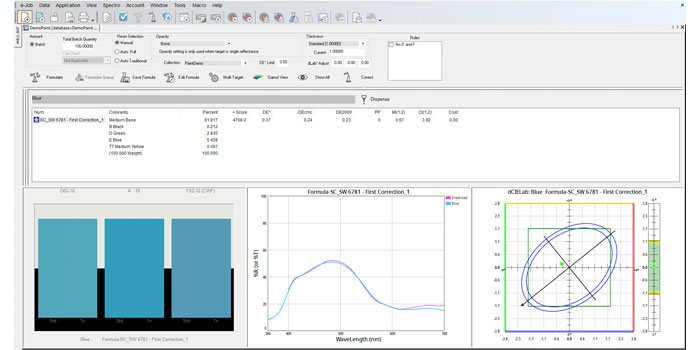

We recently launched version 10 of our Color iMatch formulation software, and it is our smartest version yet. It allows you to select cost-reducing parameters, such as lowest cost or fewest colorants, and will determine the best formula for your application. It works with legacy databases so you don’t lose what you’ve established over the years, and “learns” what works well so you can work faster and smarter as time goes on.

Using spectral matching and a completely reengineered multi-flux engine, Color iMatch can calculate recipes with or without white, from a single database, and match samples that are opaque, transparent, or translucent. When used with any of our benchtop sphere spectrophotometers like the Ci7860, the same database can be used to match samples in both reflectance and transmittance modes.

We’ve been getting a lot of questions about HOW Color iMatch works. Today we’ll take a closer look at the changes we made to the multi-flux engine that makes it so powerful and unique.

Multi-Flux: Next Generation Color Formulation

Traditionally, color formulation software has been based on mathematical theories like Kubelka-Munk, the Saunderson Correction, and Lambert-Beer. Although they are adequate for formulation, they don’t address the needs of today’s color industry.

The enhanced multi-flux engine in the latest release of Color iMatch uses a radiative transfer (RT) model optimizer similar to the well-established, 2-constant Kubelka-Munk, but also incorporates sets of “rules” to calibrate, formulate, and correct color recipes. While the multi-flux RT model has been used with excellent results in previous versions of Color iMatch and InkFormulation software, this redesigned version offers two important optimizations:

- A new correction metric, which calculates the optical data of pigments (calibration) and the concentration of recipes for more robust corrections. Color matching is achieved through fewer iterations and each step is guaranteed to reduce the distance in Delta E.

- A new sorting metric, which uses enhanced metrics to sort recipes and find the best-suited pigmentation combination for formulation and corrections in the highest ranked recipe.

Color iMatch Industrial Applications

Color iMatch uses a single mathematical model that is adapted for a wide variety of applications.

Paints and Coatings

In the past, the Kubelka-Munk model used in X-Rite’s ColorMaster software was the formulation performance benchmark in opaque paints and coatings. However, the next generation multi-flux engine in Color iMatch is equal to or exceeds the performance of Kubelka-Munk, plus offers additional formulation advantages depending on the type of paint base.

- Capable of formulating coatings in bases other than clear by extending the clear base assortment with a few additional calibration panels.

- Treats alternative bases (usually white) like additional toners with the pure alternative base and mixes of alternative base with black toner calibration panels.]

- Can build assortments using any non-opaque base. Fully opaque bases cannot be used because the multi-flux engine requires calibration panels with at least minimum transparency.

Plastics

For plastics, the formulation performance benchmark is the previous version of the multi-flux engine in Color iMatch. All of the enhancements to this generation engine improve correction performance, with a few significant improvements.

- Ensures correct pigmentation in the best-ranked recipe using the new sorting metric.

- Achieves color matching with fewer iteration steps. Each subsequent trial reduces the Delta E value toward the target until production process accuracy is achieved.

Learn More

Curious how much you can save with Color iMatch? Try our online savings calculator.

If you have a technical mind and a desire to learn more, contact us to speak with our formulation experts.