Farbmanagement ist ein Prozess zur Identifizierung und Charakterisierung jedes Geräts im Imaging-Workflow, um zu gewährleisten, dass alle Geräte die gleiche Sprache sprechen. Gemäß der Definition des ICC (International Color Consortium) sorgt ein Farbmanagement-Workflow – angefangen von der Erfassung über das Proofing bis zur endgültigen Ausgabe oder zum Ausdruck – für vorhersehbare, konstante, zuverlässige und wiederholbare Ergebnisse.

Beim digitalen Farbmanagement können sich alle am Druckworkflow beteiligten Personen auf die Spektralwerte für bestimmte Farben beziehen und die (Farb-)Präzision währenddessen in mehreren Phasen prüfen.

Digitaler Farbworkflow

Digitales Farbmanagement schließt die Lücke zwischen den Erwartungen von Markenartiklern und Designern, Mitarbeitern in der Farbküche und in der Druckvorstufe und Druckmaschinenbedienern und sorgt für gute Qualität.

- In der Designphase setzt Farbmanagement die präzise Spezifikation von Farben zur Reproduktion auf dem endgültigen Material und die Verwendung kalibrierter Monitore voraus, um zu erkennen, ob die Farben zu erzielen sind.

- In der Farbküche müssen schnell die richtigen Farbrezepturen erstellt werden.

- In der Druckvorstufe müssen alle am Workflow beteiligten Geräte kalibriert werden, um eine präzise Farbanzeige und klare Farbkommunikation zu gewährleisten.

-

Im Drucksaal müssen die an der Druckmaschine gemessenen Daten gesichert, Farbzoneneinstellungen ggf. geändert und die Ergebnisse dieser Einstellungsänderungen gemessen und zugehörige Berichte erstellt werden.

-

Während des gesamten Prozesses tragen Standards wie CxF, G7 und M-Standards zur präzisen Kommunikation bei.

Digitale Farben für das Design

Für Designer und Markenartikler kann PantoneLIVE Production - Print and Packaging dafür sorgen, dass die jeweils spezifizierte Farbe reproduzierbar ist und im gesamten Workflow richtig kommuniziert wird. Es ermöglicht Markenartiklern die eindeutige Farbspezifikation und Designern die Entwicklung eines neuen Produkts unter Berücksichtigung des vorgesehenen Substrats, um klare Erwartungen festzulegen.

PantoneLIVE ist ein sicheres, cloudbasiertes Repository mit gängigen Pantone-Farbbibliotheken und den zugehörigen abhängigen Farbstandards auf Basis von 28 gängigen Bedruckstoffen. Mit einem Spektralfotometer können Druckdienstleister die Spektralwerte für Druckbeispiele erfassen bzw. messen und sie dann während der gesamten Produktion auf Basis des digitalen Standards prüfen, um die Farbtoleranzen einzuhalten.

Digitale Farben für die Druckvorstufe

Bei vielen Farbmanagement-Systemen müssen Sie Ihre Geräte kalibrieren und ein ICC-Profil für jedes einzelne Gerät, inklusive Ausgabegeräten wie Monitoren, Druckmaschinen und Druckern, erstellen. i1Publish Pro 3 hilft professionellen Anwendern in der Bildgebung und Druckvorstufe bei der Erstellung benutzerdefinierter Profile für RGB-, CMYK- und CMYK+4-Drucksysteme. Es misst auch auf dem Bildschirm angezeigte Farbfelder, um mehrere Displays bzw. Monitore zur einheitlichen Farbanzeige zu kalibrieren und aufeinander abzustimmen.

Lesen Sie unseren Blog-Artikel, um mehr über Farbmanagement und die Gründe, warum es so wichtig ist, und über die Bedeutung von Fachbegriffen wie Gamut, Rendering Intent, Farbraum, perzeptives Rendering und Profilverbindungsraum zu erfahren.

Digitale Farben in der Farbküche

Die Farbküche ist ein Bereich im Workflow, der häufig außer Acht gelassen wird. Doch wenn hier Probleme mit der (Druck-)Farbe auftreten – ob aufgrund von Fehlern in den eingehenden Materialien oder in den Rezepturen –, können Farbfehler im Drucksaal auftreten. Die Farbrezeptierung muss nicht übermäßig schwierig oder zeitaufwendig sein. Mit der Ink Formulation-Software (IFS) können selbst Einsteiger oder unerfahrene Anwender im Handumdrehen präzise und einheitliche Farbrezepturen mithilfe digitaler Farbspezifikationen erstellen. In diesem blog wird erläutert, wie IFS auch dazu beitragen kann, die Nachhaltigkeit von Druckfarben durch die Verwendung der noch vorrätigen Restfarben zu verbessern.

Ein Spektralfotometer ist ein anderes nützliches Tool für das digitale Farbmanagement im Drucksaal. Das eXact 2 sorgt für die klare Kommunikation der Farbdaten zwischen Mitarbeitern in der Farbküche und Druckdienstleistern und Verpackungsherstellern sowie für die schnelle Erstellung präziser Rezepturen für verschiedenste Substrate, einschließlich flexibler Folien. Aufgrund seiner berührungslosen Messung verhindert das eXact 2 Verunreinigungen durch feuchte Druckfarbe und erübrigt Neumessungen.

Mehr dazu erfahren Sie in unserem Blogpost eXact 2 für Farbhersteller.

Digitale Farben im Drucksaal

Das tragbare Spektralfotometer eXact 2 kann auch im Drucksaal verwendet werden. Dieses Gerät erleichtert Druckdienstleistern und Verpackungsherstellern die Farbmessung auf Papier und flexiblen Foliensubstraten mit einem Gerät und ermöglicht die Erfassung, Kontrolle, Verwaltung und Kommunikation von Farben überall im Drucksaal.

Dank der eingebauten hochauflösenden Kamera, die über die Mantis Video Targeting-Technologie verfügt, und der einzigartigen Digital Loupe-Funktion kann das eXact 2 den Messbereich zur Prüfung von Messfeldern, Analyse der Tonwertzunahme und Messung von Druckplatten vergrößern und ein Bild der Farbmessung zum Nachweis der Konformität speichern. Mit dem eXact 2 können Sie die Rüstzeit verkürzen und gleichzeitig den Ausschuss und Farbverbrauch reduzieren. Da sich dieses Gerät auch an die InkFormulation-Software und ColorCert anbinden lässt (was weiter unten erläutert wird), können Druckmaschinenbediener die Farbqualität auch schnell auf dem Farbdisplay des eXact 2 begutachten.

Weitere Informationen über die Leistungsmerkmale und Funktionen des eXact 2 finden Sie in unserem Blogpost zu eXact 2 für Druckdienstleister und Verpackungshersteller.

Digitales Farbmanagement im globalen Druckworkflow

Selbst wenn Sie digitales Farbmanagement in jeder Phase der Produktion nutzen, müssen Sie die Abläufe zwischen allen am Workflow beteiligten Personen wirksam kommunizieren können, um die konstante und verlässliche Farbgebung zu gewährleisten. Statt jede Phase im Druckworkflow isoliert zu betrachten, ist die ganzheitliche Farbbetrachtung mit einem Farbmanagement-System ausschlaggebend für präzise und konstante Ergebnisse – angefangen von der Farbspezifikation bis zur Lieferung des fertigen Produkts.

Druckspezifikation, Qualitätskontrolle und Qualitätssicherung

Das ist das Schöne an unserer ColorCert-Suite. . Mit einer Kombination von Desktop-Modulen dient sie als Bindeglied zwischen allen Beteiligten im Workflow – ob in der Druckvorstufe, in der Farbküche oder im Drucksaal, ob an einem Standort oder mehreren Standorten – zur Kommunikation der Erwartungen an die Farb- und Druckqualität, Farbstandards, Farbtoleranzen, Druckmaschineneinstellungen und Leistung der Druckmaschine.

Geräteleistung

Ein weiterer Schritt zur Gewährleistung der Farbkonstanz in Ihrer Lieferkette besteht darin, Ihre Geräte zu zertifizieren. Mit NetProfiler, einer cloudbasierten Mischung aus Software und Farbstandards von X-Rite, können Sie die Leistung Ihrer Farbmessgeräte prüfen und optimieren. Sie verringert nicht nur Abweichungen zwischen Messgeräten, sondern kann auch Probleme bedingt durch Alterung, Verschleiß oder Umgebungseinflüsse tatsächlich beheben. Natürlich sollten Sie Ihre Geräte trotzdem regelmäßig zur offiziellen Zertifizierung an unsere Labore senden.

Gerätetransparenz

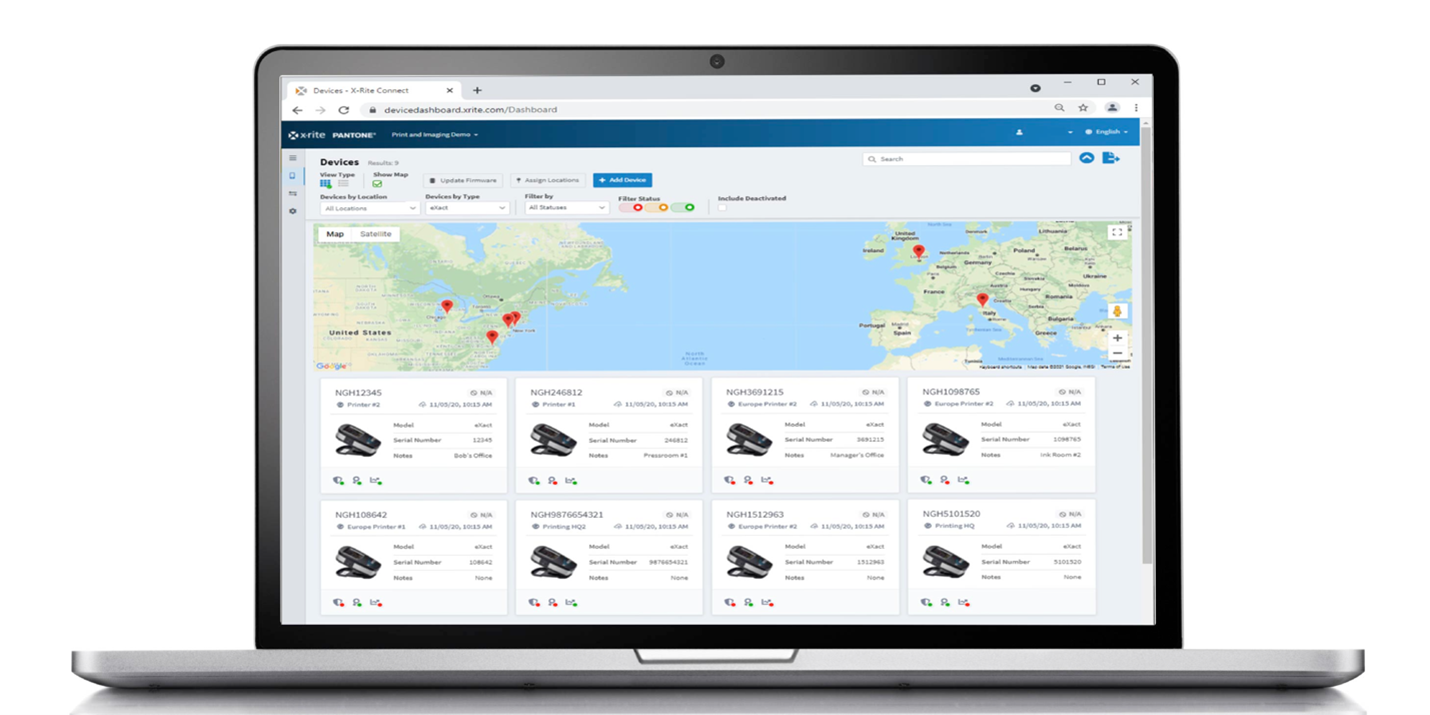

Das Dashboard X-Rite Link Link ist eine innovative Online-Plattform, die einen Echtzeit-Einblick in Ihre gesamte Geräteflotte bietet, um den manuellen Verwaltungsaufwand zu reduzieren, die optimale Geräteleistung zu gewährleisten und den Serviceprozess zu optimieren. Sie ist die ideale Lösung für Druckdienstleister mit mehreren Standorten zur Überwachung und Kontrolle von Farbmessgeräten, um den unnötigen Zeitaufwand für manuelles Suchen und Verfolgen zu vermeiden. Mit X-Rite Link können Sie aktuelle Informationen zum Gerätestatus abrufen, einschließlich Zertifizierung, Gewährleistung und Serviceplänen, Standorte für aktives Asset- und Ressourcenmanagement zuweisen und Parameter entsprechend Ihrem individuellen Workflow anpassen.

Klein anfangen und sukzessive erweitern

Durch die Verwendung digitaler Farbstandards, Implementierung von Farbmanagement in jeder Phase Ihres Workflows und zusätzliche Management-Lösungen wie ColorCert und NetProfiler entsteht ein zuverlässiger, durchgängiger Prozess. Sie müssen nicht alles auf einmal realisieren.

Ob für Einsteiger oder professionelle Anwender bietet X-Rite einige Farbmanagementlösungen, die einfach einzurichten sind und hervorragende Ergebnisse liefern – auch für Anwender mit nur wenigen Farbkenntnissen. In unserem Ressourcen-Center haben wir eine Fülle von nützlichen Farb- und Brancheninformationen zusammengestellt, damit Sie Ihr eigenes Farbprogramm erstellen und erfolgreich steuern können.

Setzen Sie sich mit uns in Verbindung, wenn Sie mit einem Farbexperten über Ihren Farbworkflow sprechen oder an unserem E-Learning-Kurs „Farbkontrollfreak“ teilnehmen möchten, um mehr über Farbmanagement zu erfahren.