Five Important Components of a Quality Control Program

Step 1: Quantify Color with a Spectrophotometer

Human vision is subjective—terms like “a bit brighter” or “slightly darker” are open to interpretation. That’s why spectrophotometers are essential. These instruments measure color by analyzing how light transfers through or reflects off a surface, producing a spectral reflectance curve—essentially a color’s unique fingerprint. This data-driven approach eliminates guesswork and ensures consistent, repeatable results.

Step 2: Set Realistic Color Tolerances

Color tolerances define how much variation is acceptable between your target and actual color. Too tight, and you’ll waste time chasing perfection. Too loose, and you risk customer dissatisfaction. Striking the right balance is key.

Tolerancing is a hefty topic. Download our free whitepaper, or watch our on-demand webinar, to learn how to select the right color model (the most common color models are L*a*b* and L*C*h°), choose the right tolerancing method, and make your tolerances actionable.

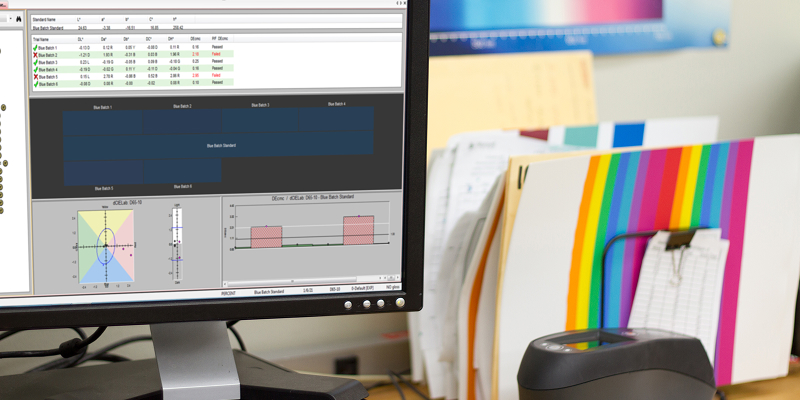

Step 3: Use QC Software to Analyze and Track Color

Quality control software like X-Rite’s Color iQC helps you compare production samples to standards, flag out-of-tolerance results, and track trends over time. It’s especially valuable for global teams, keeping everyone aligned and accountable.

Step 4: Don’t Skip Visual Evaluation

While instruments are essential, visual evaluation still plays a role—especially for less critical applications. But it’s not foolproof. Lighting conditions, training, and even color vision deficiencies can affect results.

In fact, one in every 13 men and one in every 300 women exhibit some type of color deficiency. Everyone who is involved in visual evaluation should take – and pass – the FM 100 Hue Test because a quality control person with sub-par color vision will make bad decisions. To find out if your color vision passes the test, check out our online color challenge, and share it with your friends and colleagues! (It's fun, but not a substitute for the real FM 100 Hue Test.)

Step 5: Evaluate Color Under Standardized Lighting

Viewing a sample in the parking lot is not considered standard D65 lighting. Natural daylight is dynamic. To have it agree with standard lighting you can only evaluate between 11am and 2pm using North Sky Daylight. What if it's a cloudy day? And what does third shift do?

Natural daylight is inconsistent. A calibrated light booth like the Judge LED or SpectraLight QC simulates standard lighting conditions (like D65), so you can make confident color decisions regardless of time or weather.

Ready to Improve Your Color Quality Control?

If you’re still seeing rejections or inconsistencies, it might be time to level up your process. From eLearning to on-site training, X-Rite offers the tools and expertise to help you build a reliable, ROI-driven color program.

While the investment in the tools for a quality control program may seem overwhelming, not investing will actually cost you more in the long run. We can even evaluate your current color workflow and provide ROI suggestions to pay for your investment quickly.