How to Evaluate Color on Small and Odd Shaped Plastic Samples

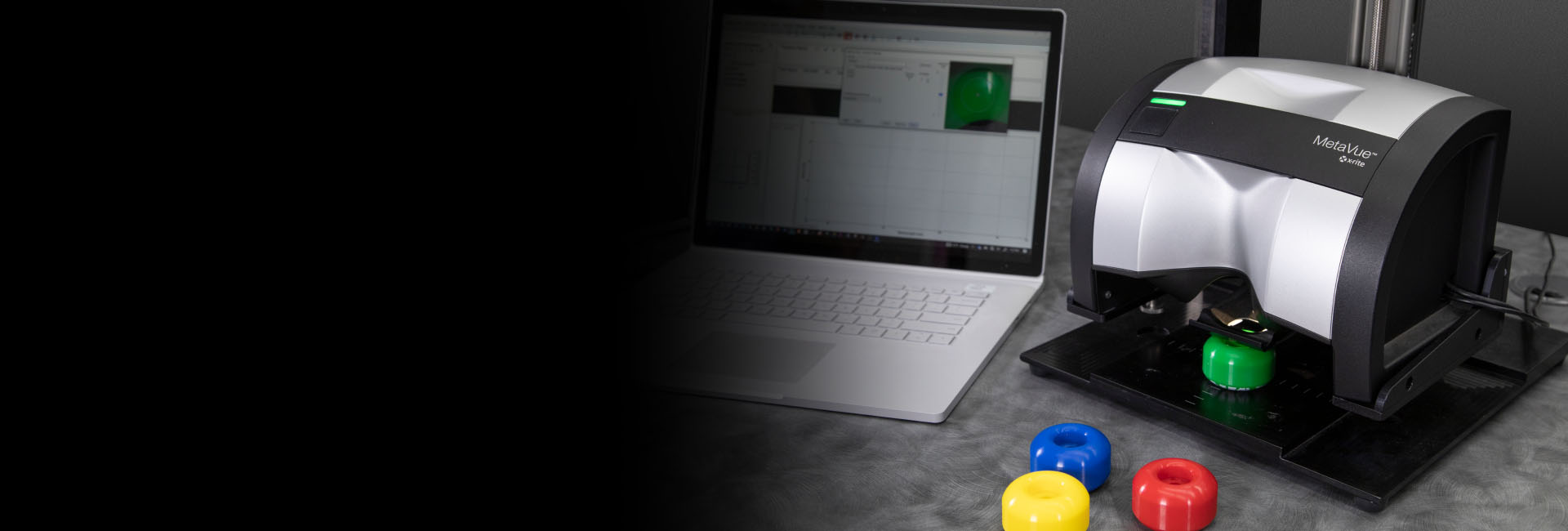

Plastic molders and plastic extruders need a solution to evaluate color on difficult-to-measure surfaces. Traditional devices are mostly suited for flat or semi-flat samples that are large enough to accommodate the aperture. The MetaVue VS3200 spectrophotometer can take precise, non-contact measurements on almost any plastic sample for less waste and fast approvals.

Challenge

Often, modifications must be made to capture accurate color on small, curved or irregular plastic pieces.

- Creating a ticket or coupon wastes a lot of plastic and provides slightly different measurements since they are not the same shape and anodized in a different bath.

- Building a custom rig for the spectrophotometer requires compensation and is difficult to repeat. The rig must be kept clean or measurement results will be impacted.

- Destructive testing is time-consuming and can pose a safety risk.

Solution

With a retractable location-aware sample positioner and aperture sizes ranging from 2mm to 12mm, the MetaVue VS3200 can capture precise measurements on a variety of plastic samples without contact. Digital targeting and on-screen preview in Color iQC enable precise alignment for repeatable spectral data, even on curves and tiny plastic pieces like cords and bottle caps.

To handle multiple sample shapes and sizes, the MetaVue VS3200 can be adapted with accessories, including an adjustable stand to measure thicker samples and a benchtop stand that converts the instrument with a sample arm for holding objects in place. MetaVue VS3200 integrates seamlessly with Color iMatch formulation software, Color iQC quality control software, and NetProfiler performance optimization software.

Results

MetaVue VS3200 captures precise color data for a fast ROI:

- MetaVue VS3200 costs about as much as modifying one production machine to produce tickets or coupons

- Eliminates the cost and countermeasures needed to modify production machines

- Eliminates destructive testing

- Saves time and plastic used to create millions of coupon impressions each year

- Measures the sellable product instead of a coupon to ensure color is on target

- Reduces rejects and waste associated with shipping incorrect color

How It Works

- Position the sample under the MetaVue VS3200 or use an accessory to present the sample.

- Using MetaVue's on-screen targeting through Color iQC software, adjust the measurement size between 2mm and 12mm.

- Choose to average all visible colors like a standard spectrophotometer or enable the smart spot feature to choose the exact spot to measure. This will evaluate all pixels and eliminate the shadows and areas that are not part of the color.

- Take the measurement and evaluate the on-screen preview, measurement data, and graphs to determine whether the sample is in tolerance.

- Use Color iQC to create portable jobs that embeds the measurement data so anyone who opens the job can review where and how the measurement was taken.

- Capture an image of the actual measurement to store along with measurement settings for an automatic audit trail.

Featured Products

A non-contact benchtop spectrophotometer with digital on-screen targeting and aperture sizes ranging from 2mm to 12mm to capture precise measurements on a variety of plastic samples, even curved and tiny pieces like cords, buttons, and caps.

Quality control software that works with MetaVue VS3200 to pinpoint the precise measurement spot, determine whether a measurement is in tolerance, and store image samples and settings for an audit trail.

Formulation software that works with MetaVue VS3200 to formulate colorant recipes and create formulation database for a variety of plastics applications.

A cloud-based blend of software and color standards to validate color measurement instrument performance. If accuracy has drifted, NetProfiler can adjust the instrument to bring it back into better agreement or notify that service is required.

MetaVue VS3200 Adjustable Stand

Allows the MetaVue VS3200 to be raised or lowered to a desired height for use in environments that measure a wide variety of sample types.

Achieve Color Success

The MetaVue VS3200 spectrophotometer along with Color iQC software can take precise, non-contact measurements to ensure plastic production stays in tolerance for less waste and fast approvals.