When NetProfiler is consistently used across the supply chain, it enables the accurate exchange of spectral color data for formulation of ink and other colorants, quality control and reproduction of Pantone or other special colors where color tolerances are tight and there is little room for error. It is an easy-to-use solution that is a critical element of an effective end-to-end color workflow. It allows users to verify and optimize performance of color measurement instruments, correcting issues caused by age, wear or environmental conditions.

With NetProfiler enabled, you benefit from:

- Standardization of color acceptance criteria and quality across locations

- Profile your fleet of instruments to ensure accurate measurement performance and consistency

- Automatic reminders when an instrument needs profiling, with a centrally controlled enterprise-wide instrument management process that ensures all instruments are performing at peak levels

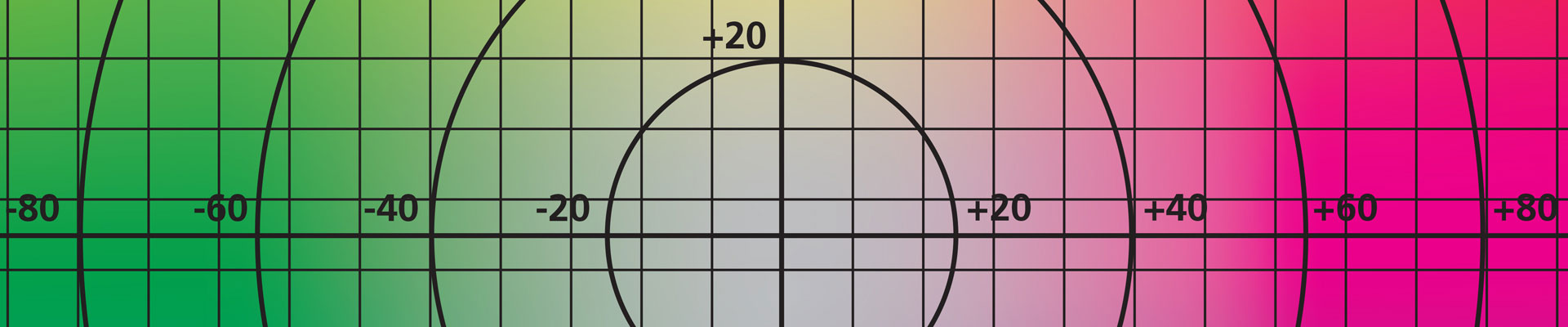

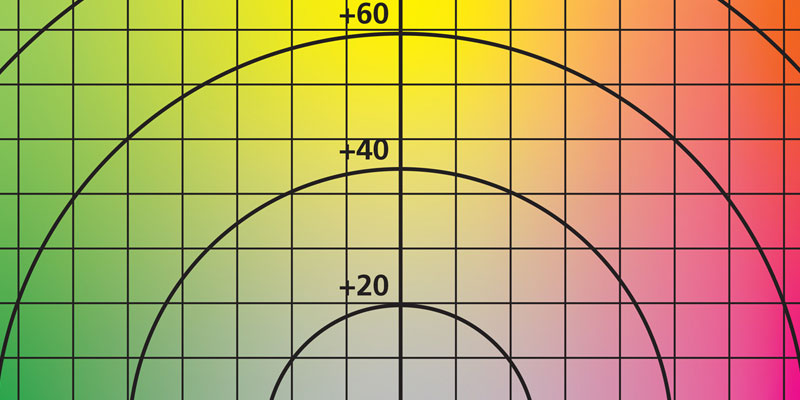

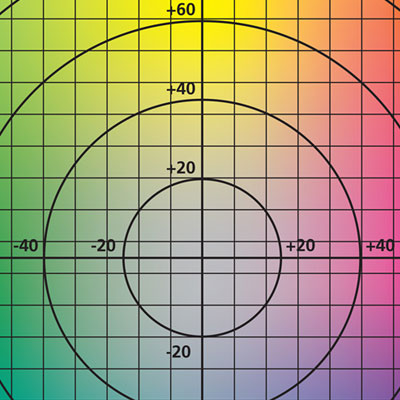

When your instrument(s) are no longer calibrated and profiled through NetProfiler, your color tolerance can be impacted dramatically. Almost immediately, you'll see colors that were previously .10 dE jump to .20 dE.

The below chart shows an individual instrument variations for all colors and why NetProfiler is key to keeping color within tolerance.

Please reach out to us if you want to learn more about NetProfiler, or continue to ensure your benchtop is profiled with NetProfiler.