How to Monitor and Control the Color of Paper Throughout Production

To ensure color quality and uniformity, many paper manufacturers pull a sample to measure in the lab, but by the time a color issue is identified most of the roll is already wasted. To keep color and brightness in harmony, paper manufacturers must constantly monitor color on fast running paper machines.

Paper Production Challenges

Many production variables can cause color shifts throughout a run. If not monitored, these errors can quickly waste an entire roll during a continuous dye run.

Many production variables can cause color shifts throughout a run. If not monitored, these errors can quickly waste an entire roll during a continuous dye run.

- Variability in raw materials, recycled paper, opacity, thickness, additives, and dye concentration can all impact final color of paper.

- Manually switching colors on the reel wastes time and materials.

- Dyes, pigments and optical brightening agents (OBAs) are expensive, making it important to get up-to-color fast

A Solution to Measure Paper Color

X-Rite's inline paper color measurement and control system includes a non-contact spectrophotometer, a custom frame to position the device over the paper roll, and quality control software to monitor color throughout the run. It serves as an early warning system by alerting the operator of a shade change and automatically adjusting dye pumps to bring color back into tolerance. It also offers automatic start up and shade changes to further minimize operator intervention. The inline system can span the entire process, from laboratory measurement to pulp, wet sheet, and measurement before reel up, to keep color and brightness in harmony. For laminated paper, it can measure the wet paper before drying with a good correlation to the finished product. It can also simultaneously monitor and control both sides of a paper using two instruments.

Benefits of Inline Paper Color Measurement

Monitoring color inline throughout production provides operators with real-time color information to make color adjustments to avoid typical operator error, costly line errors and rework.

- Achieve more stable and consistent color

- Waste up to 50% less material, time, and energy

- Attain specific color and accurate whiteness using less OBAs

- Reduce operator intervention by up to 45 minutes per automatic startup

How an Inline Color Measurement Solution Works

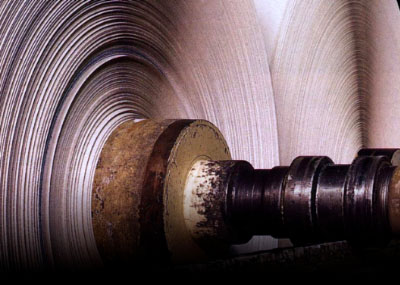

A custom frame is built to fit the paper machine. This frame holds the inline spectrophotometer over the paper roll to take measurements, moves the instrument away during a sheet break, lowers the arm to feed up the paper, and returns to position when its time to run.

Measurement is most commonly set before reel up, but this system can also monitor color at the pulp as an early warning before arriving at the machine. The inline spectrophotometer is connected to a computer running quality control or full closed loop color control software. The software uses color data captured by the instrument to calculate dye, optical brightening agent, and colorant additions and automatically adjust the dye pumps to achieve the target combinations of colors.

To make a shade change, the operator chooses the color from the database and the system will automatically adjust the dye pumps and start the run. The QC software can also report up to eight color trends in L*a*b* color space, Delta E, whiteness, and opacity so operators can understand color deviation and implement process improvements on the spot.

To make a shade change, the operator chooses the color from the database and the system will automatically adjust the dye pumps and start the run. The QC software can also report up to eight color trends in L*a*b* color space, Delta E, whiteness, and opacity so operators can understand color deviation and implement process improvements on the spot.

Featured Inline Color Measurement Products

ERX40 Inline Spectrophotometer

Measures whiteness and brightness shifts directly into the thick pulp batch (concentration of 3% to 5%) through a bypass system.

A non-contact inline spectrophotometer with standardized 45°:0° measurement geometry and spectral resolution of 1 nm to maintain tight tolerances, plus temperature and dirt detection sensors to warn of issues that could impact final color.

ESWin Quality Control Software

A customizable software solution that integrates with inline spectrophotometers to evaluate OBAs and control color quality, evaluate trends, and send instructions to correct current or emerging problems. ESWin can connect for bi-directional communication to any process control or ERP system using OPC.

When combined with an X-Rite inline color measurement instrument such as the ERX50, ESWin Closed Loop Color Control software manages color quality on continuous process manufacturing lines, displays results, and runs automatic inline closed-loop color control on papermaking and other machinery.

Achieve Color Success

An inline solution from X-Rite can help paper manufacturers monitor color in real time throughout production to keep color and brightness in harmony from laboratory measurement to pulp, wet sheet, and before reel up.