How to Evaluate Color Harmony on Assembled Goods

Assembled goods like kitchen appliances, home furnishings, and consumer electronics can be comprised of many parts, often made from different materials by different suppliers. Evaluating color in a custom fit-and-finish room under controlled lighting can ensure all parts match after assembly.

Challenges

- The appearance of color can change based on the type of light and viewing angle

- Color can shift when applied to different materials, such as coated metal, fabric, or plastic

- Components manufactured by different suppliers may follow different color programs

- All parts must match under different lighting conditions when assembled or the item will be rejected during final QC

- Large items cannot fit into a light booth to evaluate color harmony under multiple lighting conditions

Solution

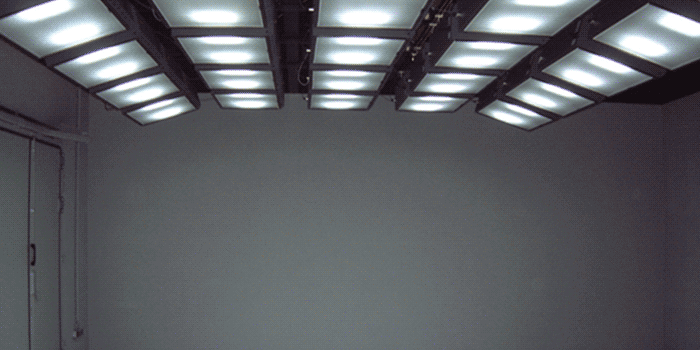

A harmony room, also referred to as a fit-and-finish room, is a custom-built visual evaluation room used to visually evaluate color under multiple lighting conditions. SpectraLight QC luminaries are mounted throughout the ceiling and/or walls to evaluate color under 7 light sources, including best-in-class dimmable filtered-tungsten halogen daylight and optional LED.

During R&D and final QC, evaluators can walk around the assembled item to evaluate color from every angle and ensure color integrity and harmony under multiple lighting conditions. SpectraLight QC is the gold standard for controlled lighting, complying with ISO: 3664, 3668, 13076, 23603, AATCC: EP9, ASTM: D1729, SAE: J361, DIN: 6173, CIE: S012/E, 51.2, and BSI: BS 950 Pt.2, for a solid quality control program.

Results

- Simulate the consumer experience for broader market acceptance

- Identify color quality issues before shipment to save time and money

- Standardize conditions for visual assessment to reduce waste

- Create a consistent color program for high quality products throughout the supply chain

- Comply with ISO: 3664, 3668, 13076, 23603, AATCC: EP9, ASTM: D1729, SAE: J361, DIN: 6173, CIE: S012/E, 51.2, and BSI: BS 950 Pt.2 standards

- Report and trace color quality for continuous improvement

How it Works

- Work with an X-Rite color scientist to determine the ideal size, shape, and bulb configuration for your fit-and-finish room. SpectraLight QC luminaires can be hung in banks as small as 1x2 and as large as your item requires.

- Create standard operating procedures to document settings for every program and create custom profiles based on requirements for light source, illumination, and other parameters to ensure consistency between evaluators.

- If desired, require part suppliers to use SpectraLight QC light booths to confirm parts are visually acceptable based on standard operating procedures before they are shipped for assembly.

- Everyone perceives color differently, so it is important to test the vision acuity of quality controllers and approvers to understand how they perceive color. The Farnsworth-Munsell Hue Test can be used to fully analyze color vision for in-house and field staff involved with color-critical operations.

Featured Products

Harmony Room

A custom fit-and-finish room for visual evaluation of large assembled items under controlled lighting. It contains SpectraLight QC luminaires, hung in various configurations, which offer best-in-class simulated daylight and a class A metamerism rating. Built-in sensors monitor and correct UV output and maintain inter-instrument agreement, and a counter shows total hours each light source has been used.

SpectraLight QC Light Booth

With 7 light sources including dimmable filtered-tungsten halogen daylight (class A) and optional LED, this top-of-the line light booth provides the most accurate daylight simulation available for optimum visual assessment. It can be used for final QC for smaller items, or by suppliers to validate accurate color on parts before shipment.

Farnsworth -Munsell 100 Hue Test

A global standard that has been used by governments and industry for more than 60 years, the FM 100 Hue Test evaluates and ranks color acuity for visual color evaluators in any industry.

Conclusion

SpectraLight QC luminaires enable checkpoints for visual approvals throughout the supply chain and ensure color harmony at final assembly. When used as a holistic solution, the SpectraLight QC reduces human error, standardizes conditions for visual assessment, and saves time and money.