Looking for the best color measurement device for your pressroom?

To help you decide, let's look at the three levels of process control to evaluate printed color.

- The most basic level is a visual comparison. However, since color vision is subjective, visual evaluation can lead to misjudgments, especially between press operators and under a different light source. If accurate color is important, visual evaluation will not be enough. You need to use a device.

- The next level of process control is densitometry. As the name suggests, densitometers do not measure color. They measure reflection - a narrow view of reflected light that represents how much ink is laid down in a particular area.

- The highest level of process control is spectrophotometry. A spectrophotometer captures a spectral fingerprint of the color, which can be used to trace all of the attributes splitting up the light evenly across the spectrum.

Read on for a closer look at the differences between a densitometer and a spectrophotometer to help you decide which is best for your printing process.

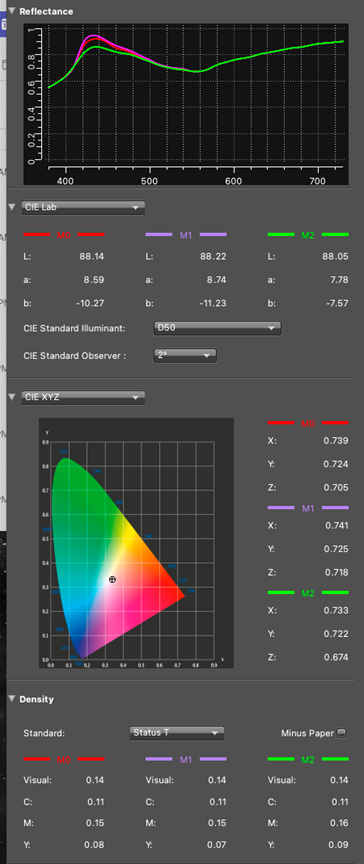

Caption: The illustration above doesn’t show a comparison of two colors; it shows the same color under different M conditions. It does show the kind of data available from spectral data. You can see here that the density values are almost identical for any M condition but clearly there is a difference in color based on paper OBAs.

What is a Densitometer?

A pressroom densitometer is designed to calculate density values for standard cyan, magenta, yellow, and black inks through a fixed response of filters. This type of reflection densitometer can tell you if you're getting the right amount of ink film thickness on the paper and maintaining it throughout the run. From ink density, you can calculate attributes like Tone Value (also called dot and dot area), Tone Value Increase (also called TVI or dot gain), print contrast, and trap.

Back when densitometry was the only process control available, status T and status E densitometers were geared toward CMYK inks. Some printing card companies used status A densitometers for reflection photographic prints because they were using inks more similar to photographic dyes than traditional CMYK printing inks.

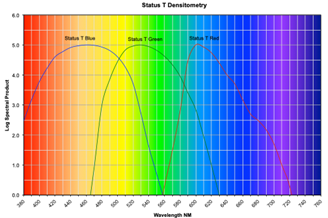

Caption: The illustration above show the fixed curves used for the status T filters. A spectrodensitometer can calculated these but also fills in the gaps along and between the filter curves

This also explains one of the main challenges with densitometers. They are geared to capture the filter response for standard CMYK inks, but the filter response, along with its detector, is not a very good predictor of status density for other inks.

The standard for densitometry was rewritten around 15 years ago to base status densities around spectral values. Most of the print metrics, especially print contrast and trapping, have a more modern metric using spectral or colorimetric data.

Recently, the industry has transitioned from a density-based TVI to colorimetric or spectral based tone calculation. That's because TVI from a densitometer doesn’t work well for spot colors and often gives numbers that don't agree with the human eye even for standard CMYK inks. Spectral or colorimetric data can do a tone value evaluation that will match what you see visually and in your design programs.

When to Use a Densitometer

Today, densitometer calculations are being superseded by spectral data metrics. Most densitometers are spectrodensitometers, although there are still a few filter based and LED based densitometers in use. A spectrodenstometer is likely to provide a better implementation of status density than a filtered or LED densitometer.

That being said, a densitometer is still a useful tool for process control if all you're doing is CMYK printing with standard ISO inks. Learn more in our Measuring Density with a Densitometer blog.

What is a Spectrophotometer?

A spectrophotometer captures the spectral reflectance - sometimes called the fingerprint - of a color. Using this fingerprint, you can trace and compare attributes by measuring color in nanometers evenly across all wavelengths of light. This type of measurement is necessary to compare a printed sample against a standard to evaluate whether color is within tolerance.

Contrary to visual evaluation, a spectrophotometer isn't tricked by surrounding colors and doesn't have a predetermined idea of the ink or paper color. It evaluates color in a completely neutral way under different observers and light sources across the visible spectrum, which is ideal for evaluating custom and spot colors using L*a*b* and LCH.

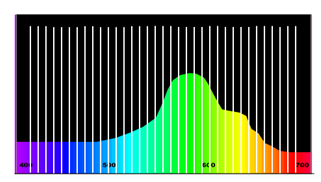

Caption: A spectrophotometer’s view of the spectrum – no predetermined fixed curves.

Although you can use a spectrophotometer to measure density by evaluating narrow bands for a particular color and picking the highest, but not many printers work that way today. It's more effective to evaluate variations in measurement data for the complete color than just solid densities.

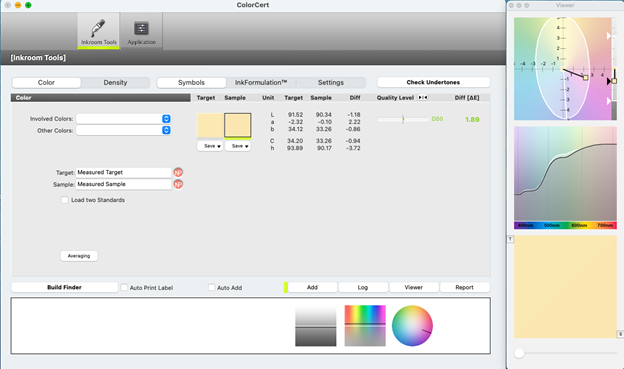

This image shows an example of a spot color measured with density and colorimetry values. Notice the density response for the primary filter is essentially the same. The colorimetery shows the same thing that your eyes do, the colors are not the same! A densitometer can mislead you into thinking you're printing the right color, but you won't be misled by a spectrophotometer.

Caption: Colorimetry will tell you about the real color appearance. If you are just looking at the primary density filter you would think the color is the same!

Learn more about using spectrophotometers for print in these blogs and resources:

- What is a Spectrophotometer

- Choosing the Right Spectrophotometer for Print and Packaging

- Controlling Color on Flexible Film

When to Use a Spectrophotometer

If you're printing special process colors, such as Extended Color Gamut (ECG) or spot colors, a traditional densitometer won't work well because these inks don't fit into the sweet spot for status density.

If you want to print to newer ISO standards, you need to use a spectrophotometer. Read our Staying Current with Standards in Print and Packaging blog for more information.

You also need a spectrophotometer to perform to G7 specifications. G7 is a widely-used process that can help you achieve repeatable, consistent control of tone reproduction and ensuring that your process colors are neutral and balanced, improving gray balance, and stabilizing color. Learn more in our What is Idealliance G7 Master Qualification blog.

Learn More

X-Rite offers a range of densitometers and spectrophotometers to meet every pressroom need. Get in touch to talk with a Color Expert about which is best for you.