Model #: tac-tac

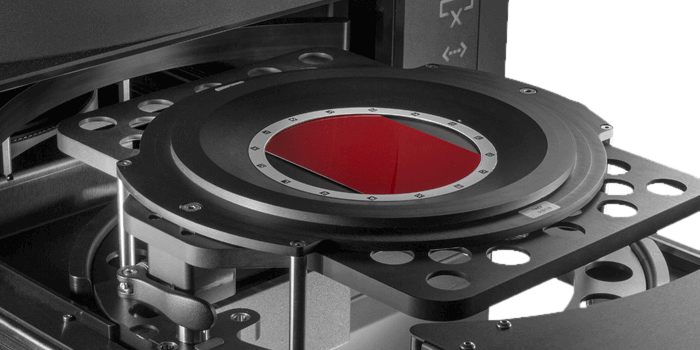

TAC7

For Scanning Appearance Characteristics

The TAC7 color scanner captures and stores color, texture, gloss and other surface appearance characteristics of physical material samples.

Capture Materials with Unmatched Realism

Measuring a material’s appearance characteristics is critical to improving quality and accelerating time to market. By accurately measuring the appearance characteristics of physical samples, the TAC7 Scanner produces digital material files that can easily be communicated and shared across the design to production workflow.

Benefits:

- Capture physical appearance properties such as color, texture, gloss, translucency and transparency in a digital format

- Simplify the maintenance and upkeep of samples by utilizing digital material libraries

- Eliminate ambiguities with precise accuracy to improve product quality and communication with stakeholders to reduce design approval cycles and accelerate time to market

- Reduce the amount of time spent manually adjusting and correcting scanned materials

- Experience more accurate renderings and improved product quality

Featured Support

Firmware: Software: See All SupportFeatured Training

Online Training / eLearning: See All TrainingYou Might Also Like

Appearance Exchange Format (AxF™)

For Communicating Material Appearance Data

AxF is a vendor-neutral file format that digitally stores and shares a material’s appearance properties across PLM, CAD and rendering applications.

Virtual Material Service

Material Scanning Service

Let X-Rite experts handle the physical material scanning for you. Transform your samples into highly accurate digital material data files for use in 3D rendering applications.