MA-T12

For 12 Angle Complete Characterization Measurements

- Measures effect and complex materials with 12 angles of measurement

- Verifies color, sparkle, coarseness and surface texture with on-board digital camera

- Enables true communication and visualization of effect finishes on complex surface structure materials

MA-T12: Fully Characterize Complex Material Finishes

The MA-T12 sets the gold standard for establishing the highest level of quality for effect and complex materials. With its 12 spectral measurement angles and color calibrated camera, the MA-T12 can fully characterize both effect and complex surface structured materials. Digital representation of a materials color and appearance can be modeled with SVBRDF (Spatially Varying Bidirectional Reflectance Distribution Function), creating an unparalleled digital workflow that ensures consistent product appearance across supply chains.

The Most Advanced Multi-Angle Spectrophotometer

Using the on-board color calibrated RGB camera for imaging, the MA-T12 can quickly and accurately evaluate and verify the color, sparkle, coarseness and texture characteristics of complex finishes with the highest level of repeatability and reproducibility. When paired with EFX QC software, this instrument is the preferred choice for establishing the strictest color standards.

Quickly Resolve Non-Compliant Products

The MA-T12 offers modern touch screen navigation, live camera measurement previews, and on-screen pass-fail indication to quickly and easily analyze non-compliant products. The MA-T12 offers a centrally located aperture with positioning pins to ensure measurement stability on samples and automatic internal calibration to reduce the risk of inaccurate measurements.

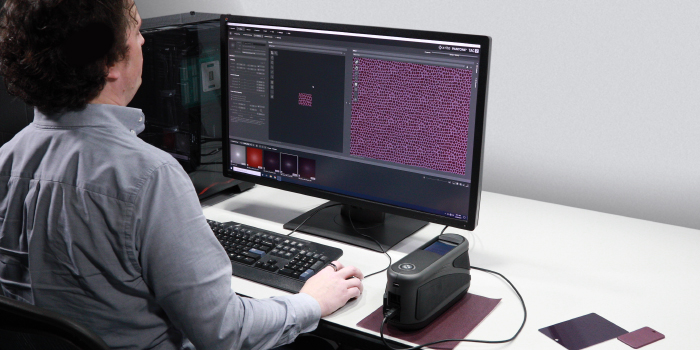

One Measurement Device from Concept to Quality Control

When MA-T12 is paired with PANTORA, Industrial Designers can digitize complex material finishes during concept and design with a handheld device that accurately captures color and appearance characteristics and renders them in their PLM software. The supply chain can utilize the same device to ensure what they are producing is within tolerance, and final inspection can utilize the device to measure and capture all aspects of a final assembled goods or vehicle.

Best-in-Class Global Service and Support

X-Rite has been helping customers master color quality for 60+ years. With global service centers and 40+ certified service partners, our comprehensive support includes technical assistance, ISO certification, Service Care Plans, training, and more. Whether troubleshooting issues, optimizing workflows, or staying current with the latest technology, you can trust our service and support teams to provide prompt and reliable assistance to minimize disruptions.

MA-T12

Specifications

| Battery | Lithium ion |

| Battery Life | Avg. 800 measurements |

| Calibration | internal white/black calibration; external white |

| Calibration Interval | 30 days |

| Camera Resolution | 40 px/mm; 1016 dpi |

| Coarseness Repeatability | 0.09% (mean error on median) |

| Coarseness Reproducibility | 1.4% (mean error on median) |

| Color Differences | L*a*b*, L*C*h°, ΔE*; ΔECMC; ΔE DIN6175, ΔE2000 |

| Communication Interface | USB 2.0 |

| Dimensions (length, width, height) | 266mm x 95mm x 128mm (26.6 cm x 9.5 cm x 12.8 cm) (10.4 in x 3.7 in x 5.0 in) |

| Humidity | 85% relative humidity max (non-condensing) |

| Illuminants | A, C, D50, D65, F2, F7, F11 & F1 |

| Illumination Colors | Polychromatic white LED with blue enhancement |

| Illumination Spot Size | 9x12mm (rectangular) |

| Industry Standards | ASTM D 2244, E 308, E 1164, E 2194; DIN 6175-1, 6175-2; SAE J1545.ISO 11664-4 |

| Instrument Display | 3.5 inch (8.9cm) color touch screen display |

| Inter-Instrument Agreement | 0.18 ∆E2000 avg. on BCRA |

| Lamp Life | 10 years lamp life |

| Languages Supported | DE, FR, EN, PT, ES, KOR, JA, Chinese, IT |

| Light Source | LED white and LED blue |

| Measurement Cycle Time | 5.5 seconds |

| Measurement Geometry | 12 measurement angles (6 illumination sources, 2 pick-ups) |

| Measurement Spot | 9x12mm |

| Observers | Colorimetric Standard Observers 2° & 10° |

| Operating Temperature Range | 50F to 104F (10C to 40C) |

| Positioning | Three positioning pins |

| Short Term Repeatability - White | 0.02 ΔE* |

| Sparkle Measurement | Sparkle Grade, Color Sparkle Parameter, Illumination 15as-15, 15as15, 15as-30, 15as-45, 15as45, 15as80, 15d Diffuse Coarseness |

| Sparkle Repeatability | 0.12% (mean error on median) |

| Sparkle Reproducibility | 1.9 % (mean error on median) |

| Spectral Interval | 10 nm |

| Spectral Range | 400-700 nm |

| Storage Temperature Range | -4F to 122F (-20C to 50C) |

| Voltage | 7.4vDC @ 2400mAh |

| Warranty | 1 year |

| Weight | 2.64 lbs, 1.2 kgs |

Support

Parts and Accessories

|

USB 2.0 Interface Cable Replacement (SE108-USBAB-03) | View Details |

Resources

Video