Reproduce Consistent Brand Color on Metal Packaging

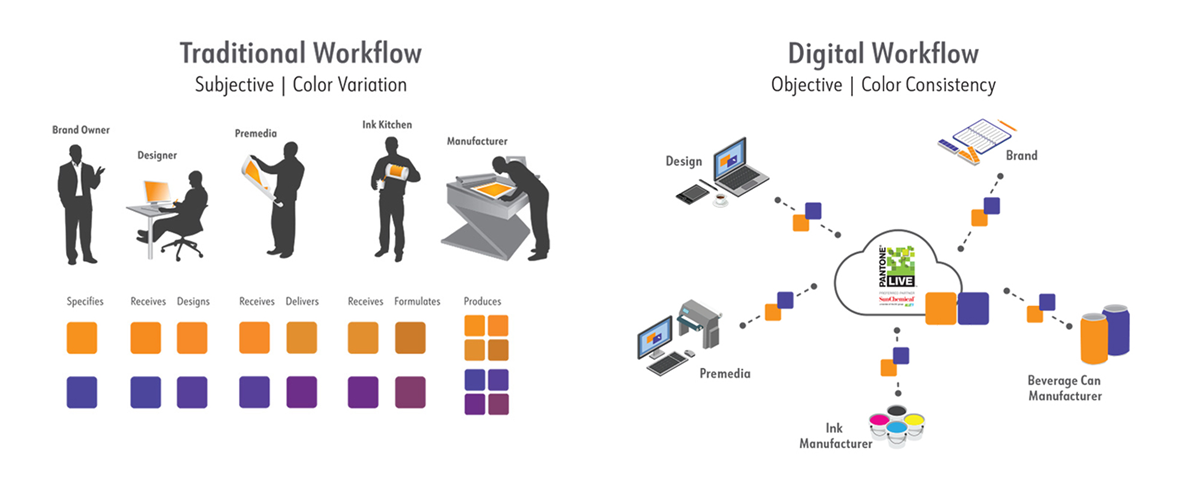

Many beverage brands choose metal can packaging because it protects their products, extends shelf life, and can be recycled repeatedly. However, the reflective properties of two-piece metal packaging can make controlling color a challenge for metal packaging manufacturers. If packaging color is not consistent on the shelf, shoppers may question product quality and reach for another brand, jeopardizing brand integrity.

Implementing color measurement for tin can packaging is the fastest, most accurate and cost-effective way to achieve original design intent and produce accurate color across processing plants.

X-Rite Pantone’s comprehensive solutions address color challenges to produce accurate and consistent color on two-piece metal packaging.

Brands like Coca-Cola have embraced X-Rite Pantone’s color measurement solutions to:

- Approve and deploy new designs faster,

- Achieve original design intent in every packaging run,

- Expand production to suppliers around the globe,

- Maintain consistency across pack types on the shelf, and

- Continue to build equity and trust in their brand.

Color Specification for Metal Packaging Design

Digitally specify and access brand color masters and material dependent standards from a secure, cloud-based repository.

- PantoneLIVE: A digital, cloud-based repository containing Pantone digital color master and material-dependent standards allowing beverage can suppliers to retrieve spectral data of achievable target colors. The world’s leading CPG brands use PantoneLIVE to share Pantone as well as their own private brand colors.

Color Measurement for Beverage Cans

Measure a beverage can at the correct height and angle to collect reliable spectral data and ensure color remains in tolerance throughout each run.

- Ci64: A handheld sphere spectrophotometer that offers simultaneous SPIN/SPEX and correlated gloss to collect reliable spectral data for statistical process control. With configurable menus, operators can view measurement procedures and data directly from the device for consistency across shifts and facilities.

- Cup and Cylinder Fixture: A sample-positioning arm to hold an unnecked beverage can, along with a bench to position the Ci64 at the correct height and angle for consistent measurements without deformation or distortion.

Quality Control During Metal Packaging Production

Evaluate whether a measured sample is in tolerance and ensure consistent color measurement between operators and global locations.

- Color iQC: A configurable software solution that enables brands, suppliers, and manufacturers to define standards, tolerances, settings, and measurement modes to ensure correct color measurement practices between operators and across global locations. Color iQC also controls key parameters like mileage and color strength, tracks trends, and reports color compliance back to brands.

- NetProfiler: A cloud-based blend of software and color standards that automatically verifies and optimizes a device’s performance to correct issues caused by age, wear, or environmental conditions. Used monthly, NetProfiler reduces variation between devices from different suppliers and identifies instruments in need of service before they result in off-color products.

Featured Resources

This study by Sun Chemical and X-Rite determines if digital data can help beverage can manufacturers communicate, design, and produce color faster and with more consistency.

Written by Sun Chemical and X-Rite Pantone Color Experts, this whitepaper explains proper color measurement procedures and techniques to capture and evaluate color data on beverage cans.

Learn how X-Rite's Cup and Cylinder Fixture and an eXact Advanced or Ci64 spectrophotometer measure cylindrical-shaped samples at the correct height and angle.