Une modification récente de la directive européenne relative à la limitation de l’utilisation de certaines substances dangereuses dans les équipements électriques et électroniques annulera, d’ici le 24 février 2025, l’exemption actuelle concernant l’utilisation du mercure dans un certain nombre de types de lampes fluorescentes à des fins spécifiques. Ces ampoules sont définies dans la clause 2(b)(4)-I d...

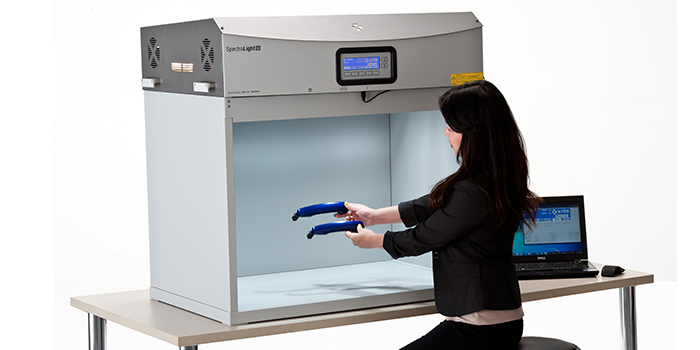

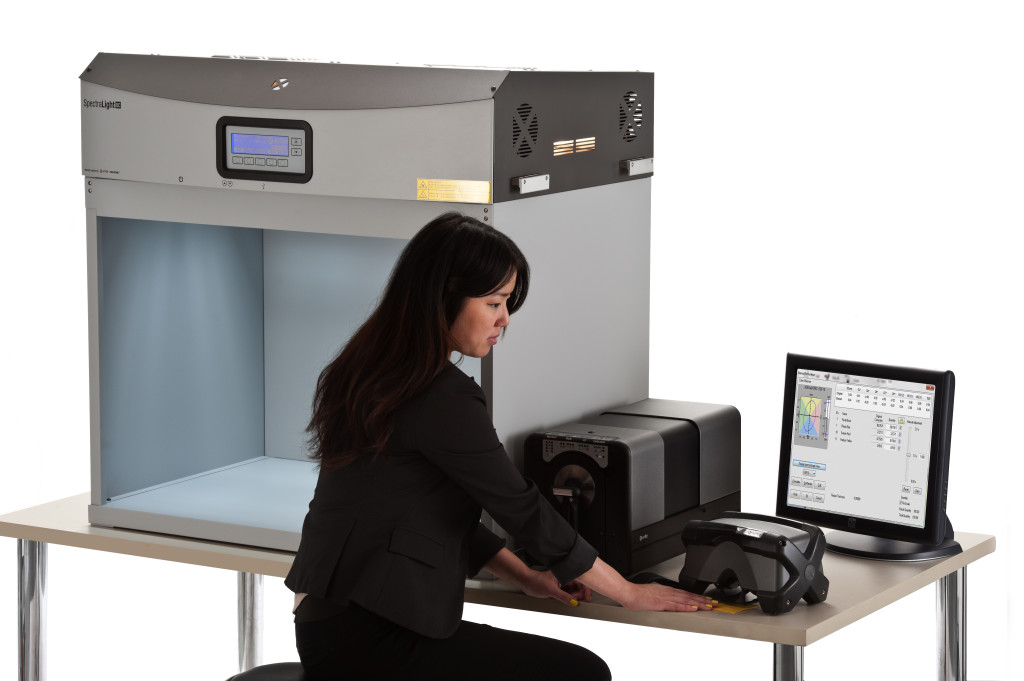

Does your quality control program include visual evaluation? If not, it should. Using the SpectraLight QC as part of a color evaluation workflow. No matter your industry, judging color is more than just measuring samples with a color measurement device. Just because a spectrophotometer says your color is within tolerance, doesn’t necessarily mean it will look right to the human eye. To minimize customer rejects, your color control process needs to include visual evaluation in a light boo...

Comme pour vous, la numérisation et la durabilité sont au cœur de nos préoccupations. Cependant, la couleur est souvent négligée lorsqu’il s’agit de développer des produits textiles. La numérisation de la chaîne d’approvisionnement textile et l’application de la gestion des couleurs à chaque étape seront finalement rentabilisées grâce à des couleurs plus précises, une pro...

As the temperature of light changes, so does our perception of color. As I mentioned in our last post, light plays a huge role in the way we perceive color. Today we’ll look at the science of color in manufacturing and photography; specifically how an object’s reflective and absorptive properties and viewing technology can impact the colors we perceive. To reflect or not to reflect… that is the question. The colors an object absorbs and reflects is determined by its material – is it metal, plas...

Light booths provide a controlled environment for judging color under different lighting conditions. They can help visually evaluate how different types of light will affect the perception of color, evaluate the color of raw materials before and after production, and ensure different components will remain uniform once they’re assembled. But not all light booths are the same. With NIST traceability and ISO 17025 accreditation, X-Rite offers worldwide competence in calibration, cert...

Une cabine de lumière de qualité est la meilleure façon de visualiser la réponse des couleurs dans des conditions d’éclairage réelles. Les cabines de lumière traditionnelles proposent des illuminants courants tels que la lumière du jour, la lumière incandescente et la lumière fluorescente afin de reproduire l’aspect des couleurs dans les magasins et après achat, sous les éclairages d’exté...

The Pantone Color of the Year announcement is always exciting. Not only does it set the stage for upcoming trends, it also provides brand owners and designers critical guidance for marketing and product development. However, those who are charged with manufacturing products and packaging with trending colors (like 2021's Ultimate Gray and Illuminating) know it doesn’t “just happen.” It takes time and effort to incorporate new colors. Whether you work in paints, plasti...

Black Friday. Not only is it the much anticipated start to holiday shopping, it’s also a day manufacturers have been preparing for all year long. Whether mass-producing holiday cards, candy canes, plastic toys, or festive clothing, accurate color is a must. Manufacturers can’t ship two of the same toy if they won’t match on the showroom floor, and holiday sweaters that are a shade off will end up at a discount store instead of a fashion boutique. Perfection is especially import...

As the industrial plastics market grows increasingly competitive and demands more sustainable practices, manufacturers need new ways to formulate and produce accurate color faster, with less waste. Digital color standards are one of the most effective tools to bridge this gap. They also enable color work and communication from remote locations. With digital color standards, brands and designers can set clear expectations with supply chains. In turn, suppliers can achieve color goals wit...

Whether you work with plastics, coatings or textiles, you must consistently achieve in-tolerance color or your product could be rejected before it even makes it to the shelf or showroom. This is especially true for brands that rely on off-site suppliers and manufacturers for raw materials and parts that come together at assembly, such as the plastic dashboard, fabric seats, and coated interior panels of a car. Even if each site produces in-tolerance color, it must be monitored an...