Color Measurement Solutions for Masterbatchers

With pressure to reduce waste and speed up time to market coming from all angles, masterbatchers must continuously evaluate processes and solutions to ensure they create the fastest and most accurate product for their customers. Complex customer specifications beyond color such as flame retardancy or UV absorbers that can make even the simplest colors challenging to formulate.

X-Rite Pantone solutions help ensure your color formulation process is at peak performance by minimizing batch color variances and ensuring repeatability. Built to help you get the most out of your historical color data to minimize overall formulation time and achieve on-time and on-spec delivery to customers and/or production line.

Customizable solutions from X-Rite Pantone provide masterbatch professionals the ability to:

- Provide optimum initial color matches and reduce number of correction step needed by increasing the percentage of acceptable 1st matches by up to 50%.

- Reduce number of cycles to acceptable matches by understanding color achievability before formulation begins.

- Reduce environmental impact and wasted material by incorporating leftover materials into recipes to work-off over time.

Trust X-Rite Pantone to achieve faster and better color so you can win and maintain more business from a diverse clientele.

Formulation for Plastic Masterbatchers:

Having the most innovative and latest solutions for formulations help to deliver the fastest and accurate color recipes while incorporating use of leftover materials. With X-Rite formulation solutions, you can reduce the steps to an acceptable match, manage recipes and assortments, provide consistent color reproduction, and reduce waste material.

-

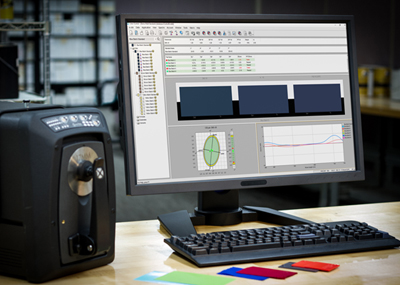

Color iMatch:

Industry-leading formulation software that gives masterbatchers the ability to increase their match rate up to 50% and cut correction steps in half, streamline workflows, tools to reduce waste and costs and get the most out of their valuable legacy data.

-

Ci7800:

This benchtop sphere spectrophotometer helps masterbatchers establish the most accurate digital color standard through its color measurement precision and accuracy to ensure optimal color matching at the start of formulation.

-

NetProfiler:

Verifies all devices are calibrated and optimized for color measurement to guarantee all devices are delivering the same measurement data, reducing inconsistencies across devices and ensuring color matching confidence.

Quality Control for Plastic Masterbatchers:

Ensure your pellets are on-spec before they are shipped out with X-Rite Quality Control solutions that have been helping our customers deliver the best masterbatch for decades.

-

Color iQC:

Provides masterbatchers with the data they need to better understand why color errors occur and identifies leading indicators to enable swift adjustments to the process and ensure final products meet color expectations.

-

Ci7800:

With leading inter-instrument agreement, masterbatchers can rest assured the measurement at formulation and QC will be consistent.

-

SpectraLightQC:

Accurately evaluate your samples and product under the appropriate lighting conditions with our SpectraLightQC which offers 7 different light sources.

Featured Resources

Learn how the right color solutions can help masterbatchers quickly achieve the best initial color matches to meet customer specifications and keep up with new color trends.

From inspiration through final product, there are many places where color can go wrong in a plastics workflow.

Better matches. Fewer corrections. Less steps. Achieve color formulation nirvana with the latest release of Color iMatch.