How to Automate Offset Press Process Control With a Closed Loop Solution

For commercial printers with an older offset press, it can be difficult to deliver the same color results as commercial printers with a new press with automated color controls. Adding a closed loop solution offers affordable automation so commercial print shops and folding carton converters can continue to compete in today's market.

Challenges

Print work is driven by specifications that require manual spot checks and ink key adjustments throughout production. Many printers struggle to quickly hit offset lithographic color targets on a sheet-fed press.

- Getting up to color can waste over 600-800 sheets of paper and ink per job.

- Innovative inks and substrates make it challenging to maintain color accuracy throughout a print run.

- As customers strive to harmonize multiple pieces, they are tightening tolerances and increasing no charge returns.

- Shrinking margins demand greater manufacturing efficiency and shorter make ready times to produce accurate color.

Solution

A closed loop solution that includes an X-Rite scanning system and integrated third party software is an affordable way to maximize performance and extend the value of an older press by monitoring color and alerting operators to any deviation. The solution can be customized based on press size – the eXact AutoScan is ideal for print shops running 29”/74cm or 40”/102cm sheet-fed presses, while the IntelliTrax2 Pro offers highly automated, non-contact scanning of 2mm color bars for 40”/102cm or larger presses – to capture process colors, spot colors, PANTONE® colors, paper color, tone value increase, gray balance, and ink density in less than 10 seconds. If color starts to shift, the software notifies the operator to update the ink keys to return to an acceptable tolerance with minimal intervention. This closed loop solution can address any client standards and print to most global graphic arts standards, including M1 for optical brighteners, M3 for measuring wet ink, and full support for G7, GRACoL, SWOP 2013, PSO, and FOGRA 51 and 52.

Results

A closed loop solution pays for itself in just 6-9 months by reducing make ready by 30%, reducing ink, paper, and labor waste by 50%, and allowing for additional jobs each day. Try our ROI calculator to see how much you can save.

The eXact Auto-Scan Pro is a game changer in our print shop. Our press operator can put the sheet on the eXact Auto-Scan Pro console and hit measure – no lining up, no fiddling or moving the head back and forth to get the laser on. This saves us time and helps us reduce any errors. The eXact Auto-Scan Pro is a must-have device for any print shop with a multi-color press.

~ Rick Fougere, General Manager, J&R Graphics

How it Works

Prepress provides a .cip or .tiff file, which includes everything the closed loop software needs to automatically preset the ink keys. The press operator chooses the print job and paper type on the touch-screen monitor, and the software does the rest to create a good starting point.

Prepress provides a .cip or .tiff file, which includes everything the closed loop software needs to automatically preset the ink keys. The press operator chooses the print job and paper type on the touch-screen monitor, and the software does the rest to create a good starting point.- The eXact Auto-Scan Pro or IntelliTrax2 Pro scanning system automatically aligns to capture a color bar in less than 10 seconds and sends color data to the closed loop software for real-time, on-screen access within 15 seconds.

- If color starts to drift, the closed loop software alerts the press operator and offers ink zone recommendations, which the operator can initiate or reject with one touch.

- To ensure color stays on track, the operator can periodically scan color data into the closed-loop software throughout the press run.

- Both scanning systems can access the PantoneLIVE database for accurate spectral target values for corporate and other spot colors, extend to the ink room for an endto-end standards-compliant workflow, integrate with NetProfiler to ensure instrument consistency, and exchange job data with ColorCert for statistical process control.

Featured Products

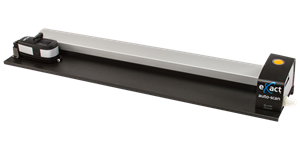

Ideal for print shops running 29”/74cm or 40”/102cm sheet-fed presses, eXact Auto-Scan Pro is a versatile press side scanning device provides flexibility for measuring color with spot, manual, and automated scanning capabilities.

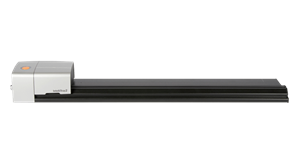

Ideal for high-end, high-speed printing/converting operations, IntelliTrax2 Pro offers highly automated, non-contact scanning of 2mm color bars for 40”/102cm or larger presses to capture process colors, spot colors, PANTONE® colors, paper color, tone value increase, gray balance, and ink density in less than 10 seconds.

Decrease Make Ready and Improve Profitability

A closed loop solution addresses a lot of pain points and frustrations in small to mid-size commercial and folding carton print shops through faster make ready, less waste, and process standardization for consistent and accurate color and a more sustainable process.