Bringing Automotive Color Measurement into Focus

The automotive industry is undergoing disruption as many face a severe financial crunch. Embracing emerging mobility options like autonomous vehicles, micro-mobility, and electric mobility along with cutting-edge designs and paint and coatings trends will help the industry become stable again. To transform these difficult times into opportunity and success, automotive manufacturers need the right tools to achieve efficient manufacturing across a global supply chain.

Color and visual appearance play a leading role in preference and brand image, making accurate color measurement and quality control integral parts of the auto making process. Achieving the same color with complex effect automotive paints and finishes that customers demand requires state-of-the-art color measurement tools. X-Rite’s portfolio of innovative solutions work together to control all aspects of paint color and appearance, from the lab to the supplier to the paint shop to the assembly line.

To deliver precise and repeatable color, X-Rite’s automotive color measurement tools can:

- Specify using physical and digital color standards.

- Design using 3D virtualization with exact optical characteristics as the real material for different parts of each vehicle.

- Create special effect and metallic paint and coating recipes using color formulation software.

- Measure using lightweight devices that fit tight intersections to characterize color, sparkle, and coarseness from multiple angles.

- Maintain 100% color quality and consistency on the production line with inline multi-angle devices that measure effect paints without contact.

- Bridge vehicle design through final assembly using QC software.

With over 60 years of innovation and proven expertise in color control, X-Rite solutions help manufacturers measure color accurately and ensure color harmony on all aspects of an automotive transportation vehicle, from the bumper to the fuel cover to the door handles and seats, for consumer acceptance in the increasingly competitive automotive market.

Commercial Vehicle Manufacturers

Accurate color is just as important for bicycles, trains, airplanes, and buses as it is for trucks and cars. As consumers look for trending effects like metallic and pearlescents, commercial vehicle manufacturers need the right tools to measure and control color and appearance throughout production.

Color Technology for the Automotive Industry

X-Rite's innovative technology and solutions for automotive manufacturers validate the color found in internal and external automotive parts for accuracy and consistency at every process step.

Instruments

- Handheld Sphere Spectrophotometer: Measures color with or without the impact of associated surface effects, including highly metallic and reflective surfaces.

- Benchtop Sphere Spectrophotometer: Enables reflection and transmission measurement to measure color across opaque, transparent and translucent materials.

- Multi-Angle Spectrophotometer: Captures measurement of metallic and effect finishes to deliver complete characterization of color, sparkle, and coarseness.

- Inline Solutions: Monitors product color as it is produced to alert the manufacturer as soon as soon as color moves out of tolerance.

Quality Control Software

- Formulation Software: Yields better matches in fewer steps and with fewer corrections through the industry’s smartest formulation engine.

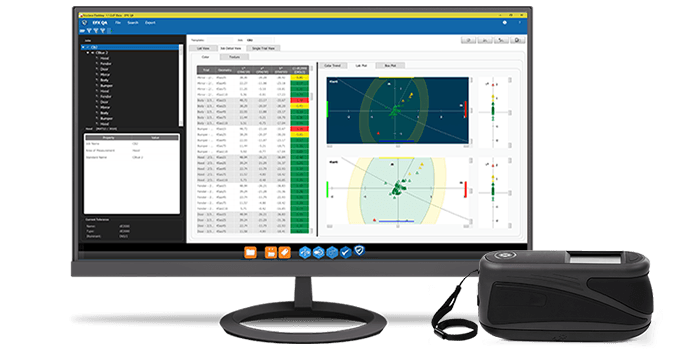

- Quality Control Software: Identifies spectral variations and ensures accurate color is achieved throughout the supply chain through adaptable and configurable software options.

- Instrument Performance Software: Verifies and optimizes performance of instruments, reducing variance among instruments.

Visual Assessment Tools

X-Rite offers end-to-end solutions to formulate, measure, control, and validate the color of all interior and exterior components for the automotive industry.

- Digital Color & Appearance: Streamlines the creation of material libraries and captures true-to-the-eye product renderings.

- Physical Color Standards: Ensures color consistency at final assembly through visual reference standards and tolerancing guides.

- Light Booth: Replicates almost any lighting environment and can be customized to fit the needs of every job and production process to ensure parts match under different spectrums.

- Fit-to-Finish Rooms: Evaluates color in a custom fit-and-finish room during under controlled lighting to ensure all materials retain color harmony to the human eye after assembly.

- Visual Assessment Tools: Evaluates an individual’s ability to discern color through easy-to-administer tests.

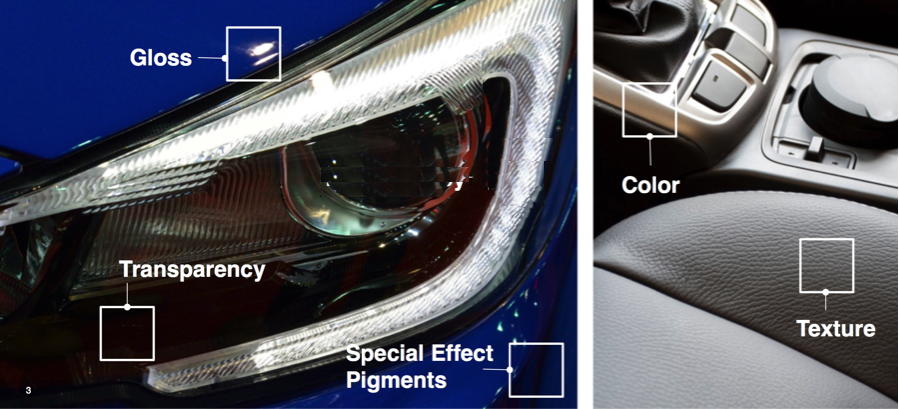

Objects have elements that are inherent to appearance, such as texture, gloss, transparency and special effects. To control color, you must understand them.

With the ability to characterize color, sparkle, and coarseness, the new MA-T Family can help manufacturers control effect finishes.

In this free 10-minute webinar, you will learn why a multi-angle is the ideal spectrophotometer to measure special effect surfaces, like metallic and pearlescent.