Model #: tac-tac

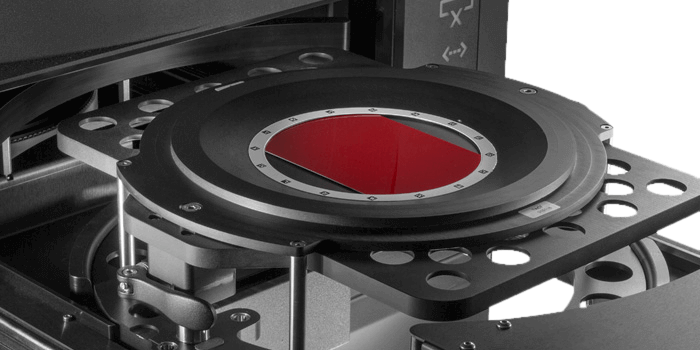

TAC7

For Scanning Appearance Characteristics

The TAC7 color scanner captures and stores color, texture, gloss and other surface appearance characteristics of physical material samples.

Capture Materials with Unmatched Realism

Measuring a material’s appearance characteristics is critical to improving quality and accelerating time to market. By accurately measuring the appearance characteristics of physical samples, the TAC7 Scanner produces digital material files that can easily be communicated and shared across the design to production workflow.

Benefits:

- Capture physical appearance properties such as color, texture, gloss, translucency and transparency in a digital format

- Simplify the maintenance and upkeep of samples by utilizing digital material libraries

- Eliminate ambiguities with precise accuracy to improve product quality and communication with stakeholders to reduce design approval cycles and accelerate time to market

- Reduce the amount of time spent manually adjusting and correcting scanned materials

- Experience more accurate renderings and improved product quality

Specifications

| Measurement Geometry | 4 monocromatic cameras at 0º, 22.5 º, 45º and 67.5º |

|---|---|

| Inter-Instrument Agreement | Not published |

| Illumination Colors | Not published |

| Illumination Spot Size | 130 mm |

| Image Contact During Measurements | No |

| Lamp Life | 10.000 hrs |

| Light Level Adjustment | Automatic |

| Light Level Sensor | Yes |

| Light Source | LED |

| Linearity | Not published |

| Measurement Spot | 130 mm |

| Measurement Time | 15 to 60 min |

| Media Thickness | 210 mm x 297 mm (flat surfaces), |

| Patch Size | 130 mm |

| Humidity | Operating Humidity: 20% to 80% relative, non-condensing |

| Operating Temperature Range | 10º C to 40º C / 50º F to 111º F |

| Storage Temperature Range | -20º C to 55º C / -4º F to 131º F |

| Material | Steel, PUR |

| Minimum Order Quantity | 1 |

| Unit Color | Black |

| Weight | 126 kg / 278 lb |

| Package Dimensions (length, width, height) | 112 cm x 112 cm x 180 cm / 44 in x 44 in x 71 in |

| Shipped Weight | 270 kg / 595 lb |

| 3rd Party Software Supported | Through PANTORA |

| Communication Interface | 1000BaseT |

| Configuration Options | Backlight option for Alphamaps (end of 2016) |

| Experience Level | Advanced |

| Import/Export Format | AxF via PANTORA SW |

| Instrument Display | No |

| Languages Supported | EN |

| Software Development Kit | TAC7 SDK |

| Status Panel | Yes |

| Battery | No |

| Voltage | 100-240 VAC/50-60 Hz |

| Wattage | 250 W |

| Calibration | Radiometric calibration (user) |

| Measurement Background | Black |

| Mobile Device Compatibility | No |

| Optical Brigtener Compensation (OBC) | No |

| NetProfiler Support | No |

| PantoneLIVE Support | No |

| Sample Preview | Yes |

| Warranty | 12 month, sold with maintenance contract |

| What's Included? | TAC7 Scanner, calibration targets, cassette, power and ethernet cords |

| Android | No |

| Apple iOS | No |

| Macintosh | No |

| Windows | Windows 7 64 bit or |

| Available Disk Space | Min. 1 TB free space |

| Connectivity | Min. 1 Gigabit Ethernet adapter |

| Display Resolution | 1080p or higher |

| Internet Connection | Not required |

| Memory | Min. 16 GB |

| Number of Displays Supported per Workstation | 2 |

| Optical Drive | Internet or usb dongle |

| Processor | Intel Xeon or Core i7 recommended (AMD CPUs not tested by X-Rite) |

| Security | User must have Administrator rights to install and uninstall the application |

| Video Card | NVIDIA Quadro or GeForce (AMD GPUs not tested by X-Rite) |

| Compatible Android Devices | No |

| Compatible iOS Devices | No |

| Data Format | AxF |

Featured Support

Firmware: Software: See All SupportFeatured Training

Online Training / eLearning: See All TrainingTestimonials

"To turn the vision of a fully automated Car-Configurator process into reality, TAC is essential. X Rite's solution enables us to reach true-to-life quality images to replicate highlights in a car's paint job." - Dr. Markus Denny, Head of Digital Image Factory

"At the core of our material process is a flexible solution for easily creating, processing and providing virtual materials easily in a multitude of different systems with the ultimate level of realistic depiction. Solutions from our partner X-Rite help us to accomplish this task." - Jan Pflüger, Digital Retail / After Sales IT Solutions

You Might Also Like

Appearance Exchange Format (AxF™)

For Communicating Material Appearance Data

AxF is a vendor-neutral file format that digitally stores and shares a material’s appearance properties across PLM, CAD and rendering applications.

Virtual Material Service

Material Scanning Service

Let X-Rite experts handle the physical material scanning for you. Transform your samples into highly accurate digital material data files for use in 3D rendering applications.